What Is Kanban Inventory Management?

Kanban inventory management is a visual system that signals to teams, managers, and vendors when to reorder parts, materials, or products. It uses actual demand to trigger restocking. This helps businesses cut waste, avoid excess inventory, and work more efficiently.

Kanban (pronounced KAHN-bahn) began at Toyota in the late 1940s. Engineer Taiichi Ohno saw how American supermarkets restocked shelves only as items were sold and applied the same idea to manufacturing. He attached physical cards — called kanban, meaning signal in Japanese — to bins to show when to produce or restock specific parts. This just-in-time (JIT) method became a core component of Lean management and helped Toyota streamline production and reduce waste. Today, Lean Kanban systems operate across industries — including manufacturing, healthcare, logistics, retail, and more — using either physical cards or digital Kanban boards.

Learn about how to do more with less in this complete guide to Lean management, and check out how Kanban has improved industries from manufacturing to software in this study of the journey from Kanban to Lean Kanban.

How the Kanban System of Inventory Management Works

Kanban inventory systems use visual signals — such as cards, bins, or digital alerts — to trigger restocking based on actual consumption. Instead of forecasting, each signal responds to real-time demand. This method helps teams avoid overproduction, reduce waste, and maintain a steady flow of materials or products.

Once in place, a Kanban system acts like a loop: When inventory is used, a signal is sent to replenish it. That signal might be a physical card attached to an empty bin or a digital alert in a dashboard. The team restocks just enough to replace what was consumed, and no more. As soon as the item is restocked, the signal returns to its starting point, ready to cycle again.

Because Kanban is a pull system, inventory moves only when needed. There’s no “push” based on forecasts or batch schedules. This makes it easier to keep stock levels lean while still meeting demand. It also gives the team a visual way to track where materials are in the process and where action is needed.

Kanban board in Smartsheet

Here’s a classic example of how the two-bin Kanban inventory system works in manufacturing:

In a two-bin system on an assembly line, two identical containers hold screws. One bin is in use while the other sits behind it. When the first bin empties, the worker removes the attached Kanban card and places it on a board labeled To Order. The second bin slides into place to keep production moving.

Meanwhile, the empty bin is sent for refilling. Once it's restocked, the bin and card return to the line, ready for the next cycle. The whole system works without anyone needing to count inventory or check a spreadsheet.

A digital version works the same way in principle:

In a hospital supply room, staff scan a QR code when a bin of IV tubing runs low. That scan triggers an alert in a digital Kanban board used by the purchasing team. The item moves into the To Order column, and a technician places a restock order.

Once the shipment arrives, the item is marked Received, and the inventory loop resets. The process is still visual and demand-driven — it just happens on a screen instead of a wall or physical bins.

Key Components of a Kanban System in Inventory

A Kanban inventory system starts with two key components: cards and bins. Cards describe the items, and bins store the items. Other usual components include a Kanban dashboard, physical or digital, with workflow columns for tracking. The system also uses work-in-process (WIP) limits and replenishment rules.

Here’s a more detailed overview of a Kanban inventory system’s components:

- Kanban Cards: These are the signals that prompt restocking. Each card includes details, such as the item name, quantity per bin, supplier, and storage location. When a bin runs low, the card is moved to a central board or dashboard to request more.

- Bins or Containers: Inventory is stored in standardized bins, often in pairs. One bin is used while the other serves as backup. When the first bin is empty, it triggers a restock while the second bin keeps work going.

- Kanban Board or Dashboard: The Kanban system uses a physical or digital board (or both) to track the status of each item. Cards move through columns such as To Order, Ordered, In Transit, and Restocked. The board gives teams an instant view of what needs attention.

Physical Kanban boards are common in manufacturing, healthcare, and warehouses. They use columns on a whiteboard or wall with physical cards or tags that are moved by hand. Digital Kanban boards are used when teams are spread out, need real-time tracking, or want automation. Software tools let users drag cards between columns, track status, and trigger alerts or updates automatically.

- Workflow Columns: Workflow columns, either physical or digital, represent stages in the restocking process. Moving a card from one column to the next helps teams see progress at a glance.

- Work-in-Process (WIP) Limits: These limits cap how many items can be in each stage at once. They prevent overordering and keep the system focused on completing one task before starting another. Depending on your industry, WIP may also stand for work in progress.

- Replenishment Rules: Every signal follows clear instructions: when to trigger, who responds, what quantity to reorder, and where the card or bin goes after restocking. These rules make the system consistent and reliable.

These optional tools can strengthen your Kanban system:

- Shelf Labels: These provide visual cues that help team members quickly identify bins, product categories, or reorder points without needing to read every card.

- Barcode Scanners: Scanning devices track products, bins, or cards when they’re moved. This can trigger digital updates, reduce manual tracking, and add traceability.

- Digital Kanban Apps: Software tools (such as Smartsheet, Kanbanize, or Trello) display real-time board views, allow for drag-and-drop updates, and automatically track order status across teams.

- Supplier Integrations: Some systems link directly with vendors. When a Kanban card is triggered, an order is sent automatically, speeding up replenishment and reducing administrative work.

- Mobile Devices: Teams can use tablets or phones to scan items, update card status, or monitor dashboards on the floor. This helps teams stay connected to the system without being tied to a desktop.

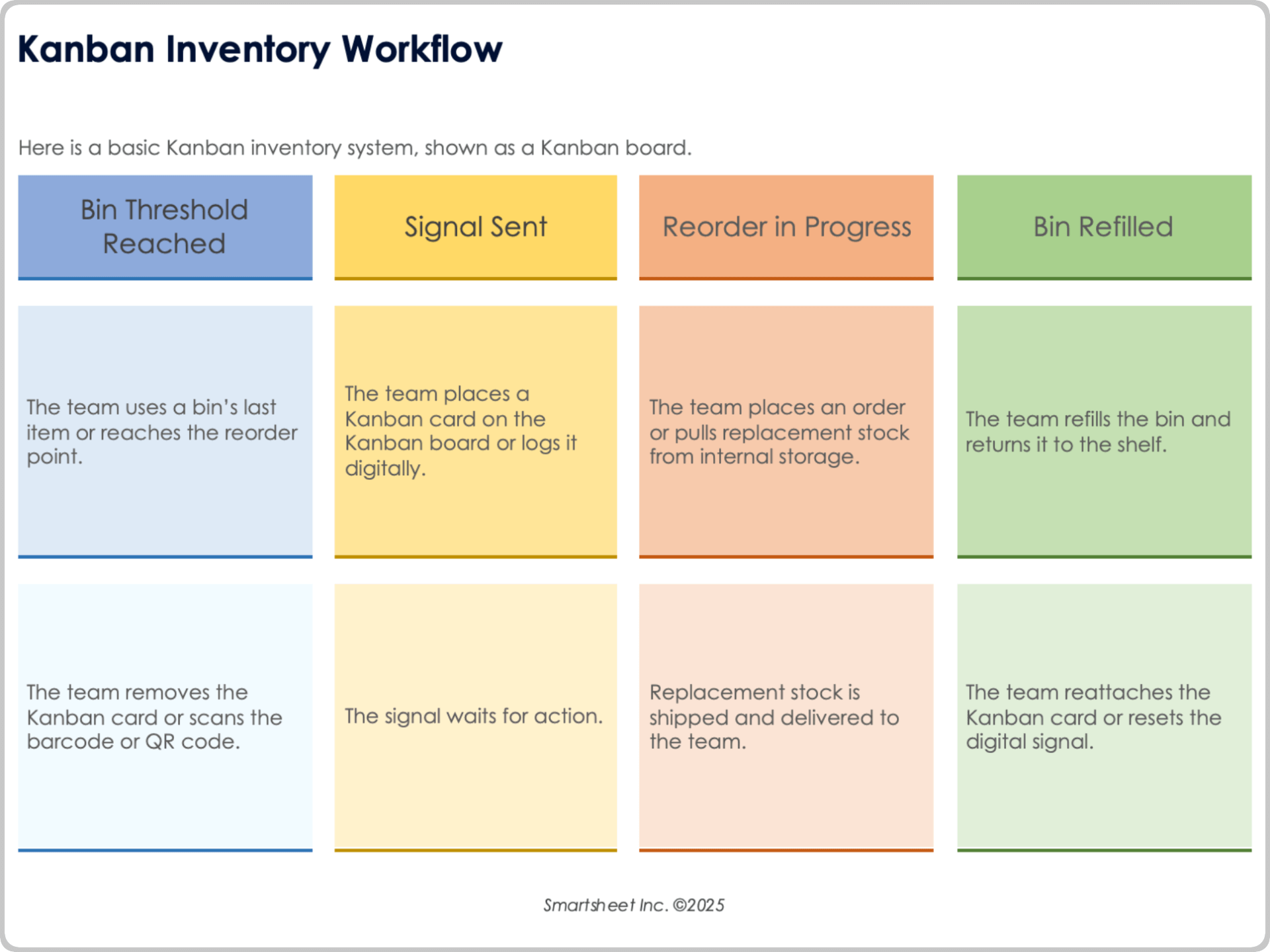

Kanban Inventory Flow

In a Kanban inventory workflow system, the process starts in the bin, and the team moves the card or notes the item’s progress when they need to reorder. From there, the team sends the signal to initiate the replacement order and refill the bin.

Download the Kanban Inventory Workflow in Adobe PDF

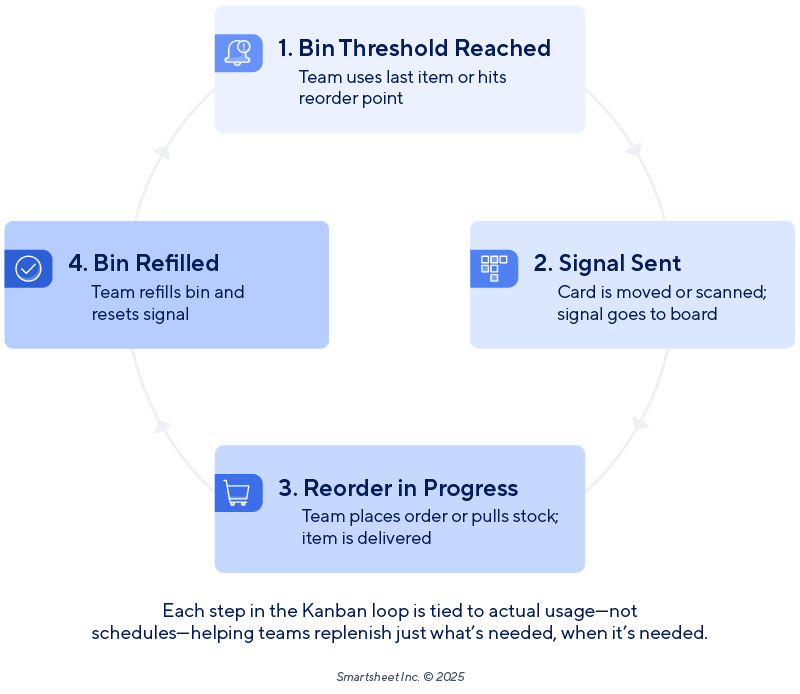

You can also view the Kanban inventory flow system as a cycle of four steps. When you reach the fourth step and refill the bin, you go back to the first stage until you reach the bin threshold.

How to Calculate the Number of Kanban Cards (or Bins)

To set up a Kanban system that works, you’ll need to figure out how many bins or cards are needed to keep your process going without running out of stock. There’s a simple formula for that, often called the Kanban quantity or Kanban card formula.

Here’s the basic version of the Kanban card formula:

Number of Kanban cards =

[Average daily demand × (lead time + safety stock days)] ÷ quantity per bin

Or, put another way:

C = [D × (L + SSD)] ÷ S

Where:

- C = Number of Kanban cards (or bins)

- D = Average daily demand

- L = Lead time (in days) to restock

- SSD = Safety stock days (a buffer to cover variability)

- S = Quantity per bin (or the amount each Kanban signal represents)

For example, you use 40 units of a part each day. It takes three days to restock it, and you want one extra day of safety stock. You keep 50 units in each bin. Here’s how the formula progresses:

C = (40 × (3 + 1)) ÷ 50

C = (40 × 4) ÷ 50

C = 160 ÷ 50

C = 3.2

You’d round up to 4 Kanban cards. That means you’d want four bins in rotation for that part, each holding 50 units.

Here are a few tips for using this formula:

- Always Round Up: It’s better to have a little extra than to run out.

- Use Real Lead Times: Don’t guess — use your actual supplier or restocking times.

- Review Regularly: If demand or lead times change, so should your Kanban sizing.

- Budget Buffer Time: You might need more buffer time if demand is unpredictable or suppliers are slow.

How to Implement a Kanban Inventory Management System

To implement a Kanban inventory system, first map your workflow. Then design your signal process, set bin quantities, create rules and responsibilities, train your team, and run a small-scale pilot. Review regularly and adjust your system as you learn what works best.

Follow these step-by-step instructions on how to implement a Kanban inventory system:

1. Map Your Inventory Workflow

Do a full walkthrough of your inventory process, from receiving to storage to usage to restocking. Talk to the people who work with inventory every day to get their input. Then sketch out all the information into a rough diagram that helps you spot gaps or delays, and identify where things slow down or get overstocked. Once you have a rough outline or workflow map, identify where restocking decisions happen. These will become your Kanban signal points.

Make sure your system and workflow map are clearly labeled and outdated stock is removed. Keep improving upon your lead time data.

Andrew Lokenauth, a financial consultant who advises companies on operational strategy and inventory management, emphasizes that getting the process right means starting with the people on the floor.

“I always start with a week of just watching the floor workers, learning their process, and getting their input on card placement and bin sizes,” Lokenauth says.

2. Design Your Kanban Setup

Set bin quantities based on real usage and supplier lead times, not guesses. For each bin, create a Kanban card identifying the item name, quantity, vendor, and location.

Have a clear place where signals are collected — a wall board, a drop box, or a shared digital board — and a clear system for what happens once a signal is triggered, who has to respond, and how the card is returned after restocking.

Kiara DeWitt, BSN, RN, CPN, is the founder and CEO of Injectco, a chain of medical aesthetics and weight loss clinics. She built her own Kanban system from scratch without external consultants.

“Don’t overdesign,” DeWitt says. “A Sharpie and painter’s tape can teach your staff 90 percent of what they need to know. Add fancy dashboards later.”

3. Set Rules and Limits

Setting work-in-process (WIP) limits means deciding how many items or orders can be in each stage at once. This keeps the process moving smoothly. Assign clear rules and responsibilities for what happens after the restock signal is triggered, such as who places the order, who moves the card or bin, or who changes the inventory status within the system. Post these rules where people can easily see or access them.

It’s also important to plan for exceptions or emergencies, such as when a card is lost or demand unexpectedly spikes. Lokenauth stresses the importance of having a fallback plan.

“You need a backup plan for when things break down,” he says. “I make all my clients create a Kanban override process — a documented way to bypass the system when needed without creating chaos.”

4. Train Your Team

Training the team is crucial when implementing a Kanban inventory management system because the system involves people understanding and following specific visual cues. Make sure everyone who is involved in the process understands the value of it and is on board.

Use real inventory in training. Assign a few trusted team leaders to guide people and let them walk through the process from start to finish. Cheat sheets can help them remember every stage of the process. DeWitt warns that even a well-designed system fails if the team doesn’t follow it. “Train your team to respect the board,” she says. “It means nothing if people skip the steps.”

5. Run a Pilot

Once you complete your training and set up your system, it’s time to run a pilot. Choose a small, high-usage area or item group to start. Let the system run for a few weeks and watch how cards flow, how restocking happens, and where it stalls. Gather feedback from everyone involved in the system, and adjust on a continuous basis — and start small if needed. Lokenauth recalls a client who learned the hard way not to start too big.

“One of my clients wanted to roll out Kanban across their entire warehouse — $12 million in inventory,” he says. “Big mistake. We ended up scaling back to just their fastest-moving SKUs in one product line, got that working smoothly for two months, then expanded.”

6. Review and Improve

As you roll out your system, track performance and metrics such as cycle times, order errors, and stockouts. Note when things change, and adjust your timeline or various other factors as required, and train workers on a regular basis so that your team is current on the system as it is improved. Make sure to celebrate wins and encourage the team so that people stay motivated.

In a few simple steps, you can create any kind of Kanban board in Smartsheet. Also, see these Kanban card examples across industries for more inspiration.

Alisha Navarro is the founder and CEO of 2 Hounds Design, a North Carolina-based manufacturer of dog harnesses, collars, and leashes. Her team uses a physical Kanban system to manage dozens of color and size variations on the production floor. Over time, she’s learned that success depends on staying flexible and adjusting the system as needed.

“This isn't a one-time ‘set up and forget it,’’ she says. “Lean is a continuous improvement game.”

Check out our complete guide to Lean process improvement for a step-by-step guide with examples and case studies.

Benefits of a Kanban Inventory System

A Kanban inventory system helps teams reduce waste, prevent stockouts, and simplify restocking. It triggers replenishment based on actual usage, not forecasts, so businesses can keep inventory lean and operations efficient without guesswork or constant oversight. While the idea is simple — reorder only what’s been used — the results are far-reaching.

Here are some of the most common and measurable benefits of a Kanban inventory system:

- Less Waste: Kanban helps teams reduce excess stock by tying inventory levels directly to actual consumption. That means fewer expired items, smaller backrooms, and less capital tied up in materials that just sit on the shelf.

“The benefit of Kanban is I can set the inventory levels based on the number of cards available,” Navarro says. “If there are enough cards to have 10 pieces in stock, and we are consistently running out of that size or color, I can add another card and adjust. Or if we are consistently overstocked on a size or color, I can pull one of the cards out of rotation.”

- Fewer Stockouts and Surprises: Kanban helps teams respond before inventory hits zero. Signals are triggered by use, not schedules, so replenishment happens in time to avoid delays.

“To be honest, Kanban saved my business,” says Injecto founder DeWitt. “We cut product waste by 40 percent in the first quarter, avoided three inventory emergencies, and gained back two hours a week per lead injector.”

- High Visibility: Kanban systems make work visible. Whether you’re using cards, bins, or a digital dashboard, the entire team can see what’s been used, what needs to be reordered, and what’s been refilled — no need to dig through spreadsheets or email threads.

“Clear systems reduce friction,” says DeWitt. “And that gives you speed without chaos.”

- Smoother Flow and Faster Turnaround: Because replenishment is tied to real consumption, items flow through the system without bottlenecks or bloated batch ordering. The result is a more consistent rhythm across teams and locations.

“Our goal is to use 100 percent of the inventory and ‘turn’ it repeatedly throughout the day,” says Navarro, the founder of 2 Hounds Design. “We know it takes about two hours to get a card through our system, so our inventory levels are based on roughly how many of those harnesses we will use so that we always run close, but never run out.”

- Clear Roles: Kanban creates transparency around responsibilities: who triggers, who orders, who restocks.

- Flexibility: Kanban systems are flexible by design. Teams can add or remove cards, adjust quantities, or tweak reorder rules as they learn what works best for each product.

Navarro refined her system at 2 Hounds Design through hands-on trial and error.

“We started with 30 harnesses at a time on a card, and that was a joke!” she says. “It took us over a day to get a card through the entire process (with all of the other cards lined up in front of the one we just sent through). Then we cut it to 15 harnesses on a card, then 10, then five, then three, then back to five — as we found that five was the optimal number of harnesses to justify the time it takes to change the thread and bobbin on the machine.”

- Scalability: Kanban starts simply — with physical cards, bins, or shelves — and can scale into hybrid or fully digital systems as your needs grow. The core logic stays the same, even as your tools evolve.

Carl Jacobs is the co-founder and CEO of Apicbase, an inventory platform used by restaurant groups across Europe and North America. In response to challenges with physical Kanban systems, his team developed digital tools, such as low-stock alerts and signal tracking, to help streamline replenishment processes.

“Start with what’s easiest for your team to adopt,” Jacobs says. “But build toward digital if you want scale, consistency, and better forecasting.”

Challenges of a Kanban Inventory System

Kanban systems are straightforward and their benefits are clear — but the implementation isn’t always smooth. The most common problems stem from inconsistent execution, lack of training, unreliable suppliers, or unclear processes.

Here are the top obstacles for a Kanban inventory system and how to avoid them:

- Missed Signals: When a team misses a Kanban signal — whether due to distraction, habit, or lack of training — replenishment doesn’t happen on time. This is one of the most common breakdown points in physical systems.

Jacobs, CEO of Apicbase, has seen it firsthand while helping restaurant teams manage stock across multiple sites.

“We’ve seen cards get skipped or bins refilled without triggering the reorder process,” he says. “To fix this, we built in digital checks and low-stock alerts in Apicbase that automatically notify procurement teams when stock hits a threshold. My advice: If you’re relying only on physical cards, expect hiccups, and create clear accountability for who moves and monitors them.”

Lokenauth has seen similar problems with teams not using Kanban cards properly.

“The biggest headache I keep running into is card discipline — people either losing cards or not moving them at the right time,” he says. “At one manufacturing plant, we lost about 30 percent of our cards in the first month.” To fix the problem, Lokenauth says the team made the cards bigger (“Way bigger than you’d think necessary,” he says) and started using different colored cards for different areas.

- Supplier or Lead Time Problems: Some vendors can’t handle frequent, small orders or respond quickly to signals. “Supply chain disruptions can wreck a Kanban system,” Lokenauth warns. “I learned this the hard way with a client last March when their main supplier had a six-week delay. Now I always build in safety stock triggers and alternate supplier arrangements before implementing any new system.”

- Scope Overreach: A full-scale rollout increases the risk of confusion and failure. “Start small and scale,” Jacobs says. “Don’t Kanban your entire operation on day one. Choose one high-moving item or process, such as tracking fresh produce or packaging, and test the system there. This makes it easier to spot workflow issues early.”

- Lack of Clear Ownership: Even when a Kanban board is well-designed, it won’t work if no one owns the process. If roles such as card mover, order placer, or bin refiller are left vague, signals sit idle, and inventory gaps grow. Assigning ownership — ideally to a role, not just a person — keeps the loop moving.

Inconsistent Training or Habits: Kanban systems often launch smoothly, but over time, teams can slip into old habits, especially if no one reinforces the process. New hires may not be trained, and seasoned staff may cut corners when things get busy. Without consistent reinforcement, even a well-designed system breaks down.

Yogesh Choudhary, CEO and co-founder of FieldCircle, helps field service and inventory-heavy businesses implement practical, scalable systems tailored to daily operations.

“Even the best Kanban system fails if people forget to move cards or scan items,” he says. “A 10-minute weekly refresher goes a long way.”

He also stresses the power of simple visual cues to make the process easier to follow. “Many of our clients in service and maintenance industries benefit from using simple visual triggers, such as color-coded bins or barcode labels, to signal when stock is running low.”

Examples of Kanban Inventory Systems in Action

Kanban works across industries, from high-mix manufacturing to multisite clinical operations. These two real-world examples show how flexible and scalable the system can be:

- Physical Kanban in Manufacturing: At 2 Hounds Design, a manufacturer of dog harnesses and collars, a Kanban system helps manage production across dozens of color and size variations. Each laminated card represents a “recipe” for producing five harnesses and follows the product through every stage of manufacturing.

“We have cards made and laminated that have the ‘recipe’ (cuts, measurements, instructions) for how to make five dog harnesses — and the color and size are specific to that Kanban card,” says founder Navarro. “The cards pass to the beginning of the process (webbing cutting) and follow the box through the entire manufacturing process until the harnesses are inspected and completed and hanging neatly on a wall.”

The number of cards determines inventory levels. If stock runs out, they add a card. If items sit too long, they pull one.

- Hybrid Kanban in Healthcare: Injectco, a network of eight medical aesthetics and weight loss clinics founded by neurology nurse Kiara DeWitt, uses a hybrid Kanban system combining physical bins with digital tracking.

“I manage inventory across eight clinics and built our Kanban system from scratch — no consultants, no templates, just hands-on iteration,” DeWitt says. “My team oversees medical supplies, injectables, lab materials, and training kits using a fully customized hybrid Kanban system that keeps our workflows lean and our waste minimal.”

Each supply item has a labeled bin and a QR code. When the last unit is used, staff scan the code, which triggers a restock request and logs the action in a cloud-based tracker.

“If you touch the last unit, you scan or you stop — no exceptions,” DeWitt says. “Track violations like you would any other workflow error. It is process protection, not micromanagement.”

The results were immediate: 40 percent less product waste, two hours of time saved per injector per week, and far fewer inventory disruptions.

“It scales because it respects reality,” she says. “Clear systems reduce friction, and that gives you speed without chaos.”

Kanban Inventory Control Software

Kanban inventory software automates the process of tracking, replenishing, and managing stock based on real-time usage. These tools reduce manual work, improve visibility, and help ensure that teams restock only what’s needed — at the right time and in the right amount.

The right solution depends on your business size, complexity, and budget. A small operation might begin with a manual or hybrid system, using bins and QR codes, before moving to a full digital platform. Larger organizations with more inventory and moving parts often benefit from software that supports automation, multi-location tracking, and advanced reporting.

Many modern systems integrate barcodes, QR codes, or RFID tags, allowing inventory to be updated automatically as items are scanned or moved. Digital Kanban platforms can also generate restock orders, calculate lead times, and track supplier performance.

For businesses considering their options, here’s a guide on how to choose the right Kanban software for your company.

Using Smartsheet to Create a Kanban Inventory Board

Board View in Smartsheet makes it easy to create a Kanban board that tracks inventory requests from signal to restock. While you might be more familiar with Kanban boards that display tasks in a workflow, their flexible layout also works well for visualizing inventory flow in a Kanban inventory management system.

Follow these steps to turn an inventory management sheet in Smartsheet into a Kanban workflow:

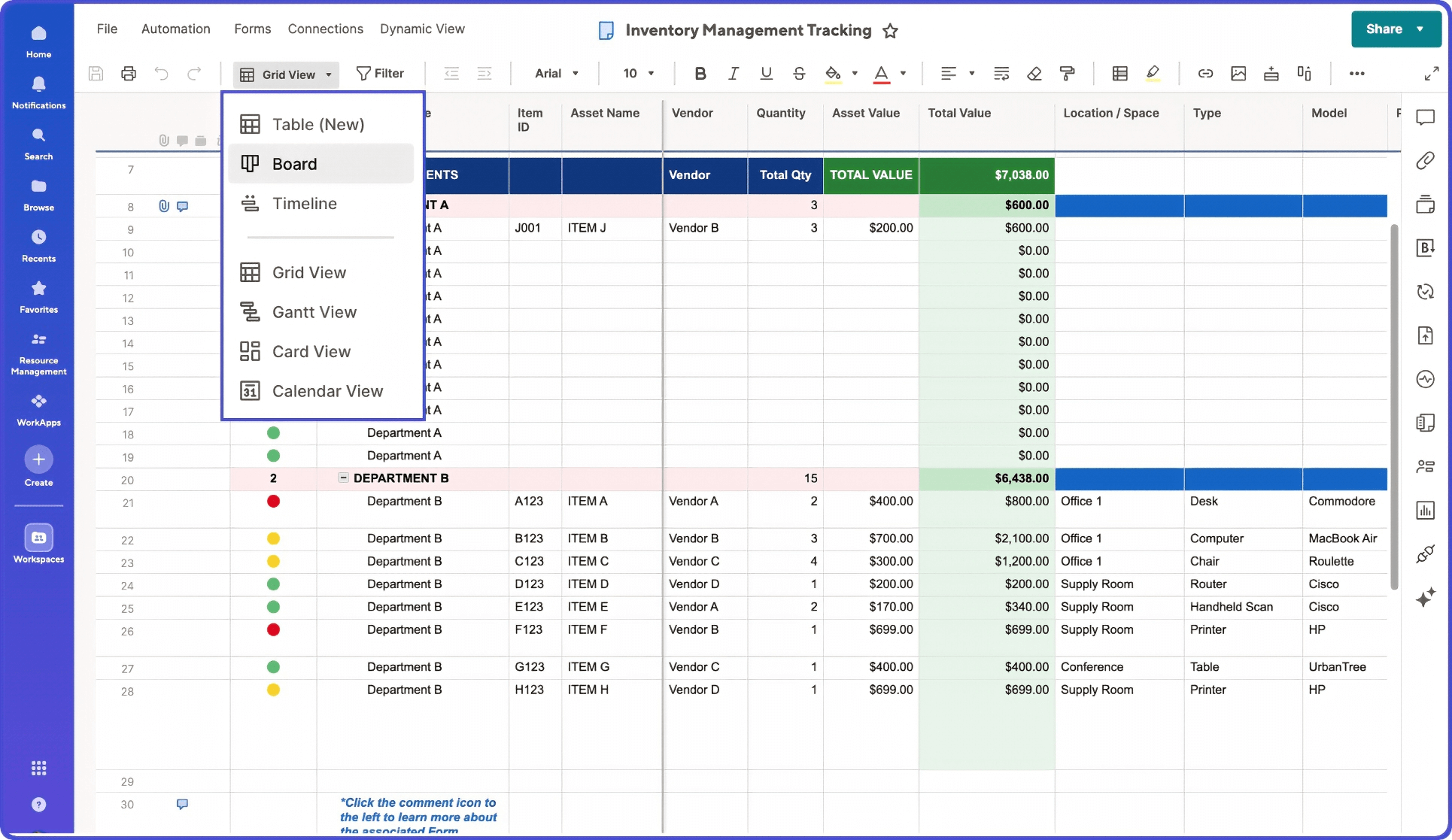

- Open the inventory management sheet in Smartsheet. Click Grid View in the ribbon and click Board.

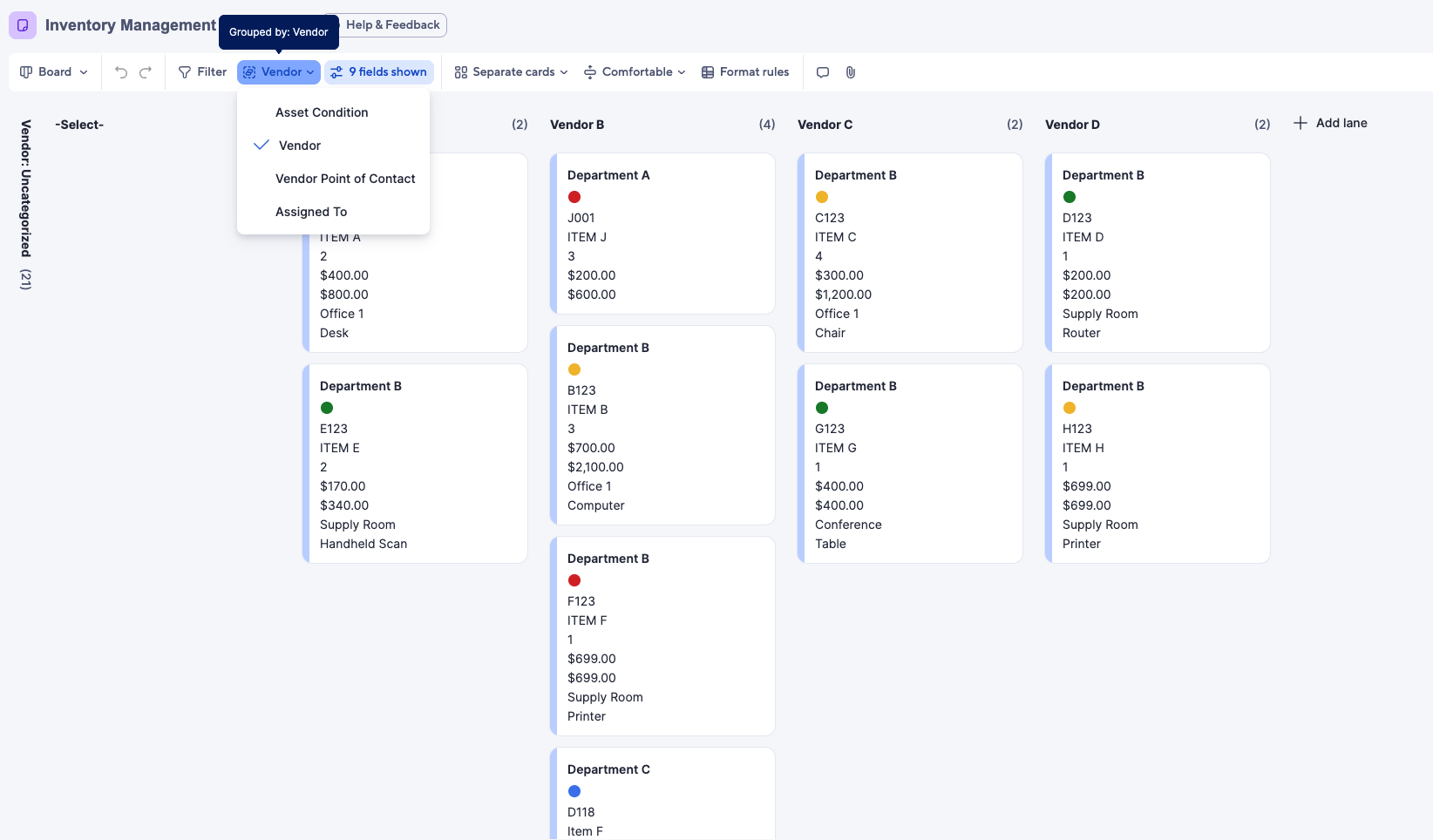

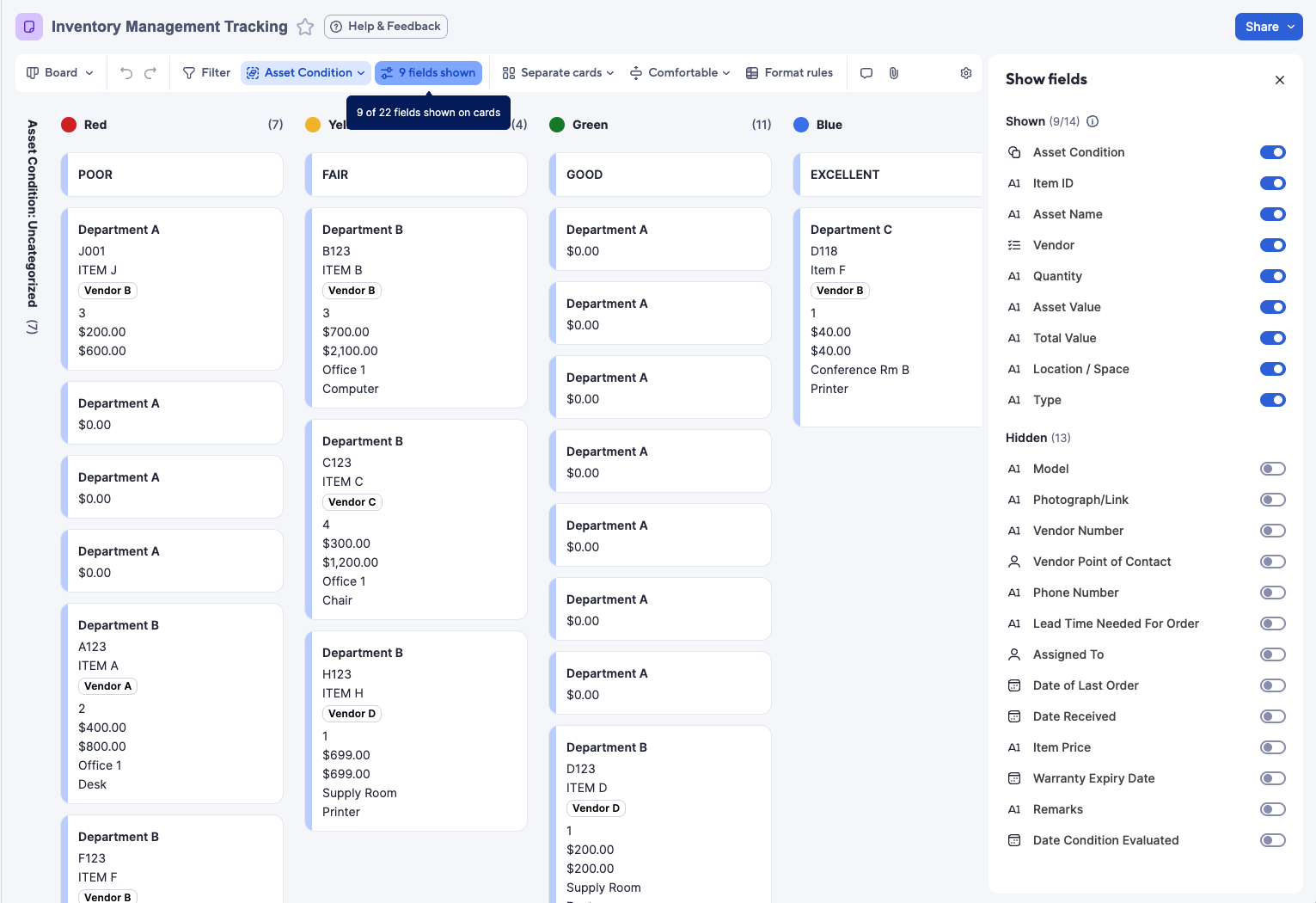

- The view will change to Board View, resembling an inventory Kanban management workflow. To switch the column headers, click Vendor in the ribbon and choose another option, such as Asset Condition.

- Click the Fields Shown in the ribbon to customize the information on the Kanban board. Use the corresponding slide buttons to reveal what elements reshow and hidden on each card.

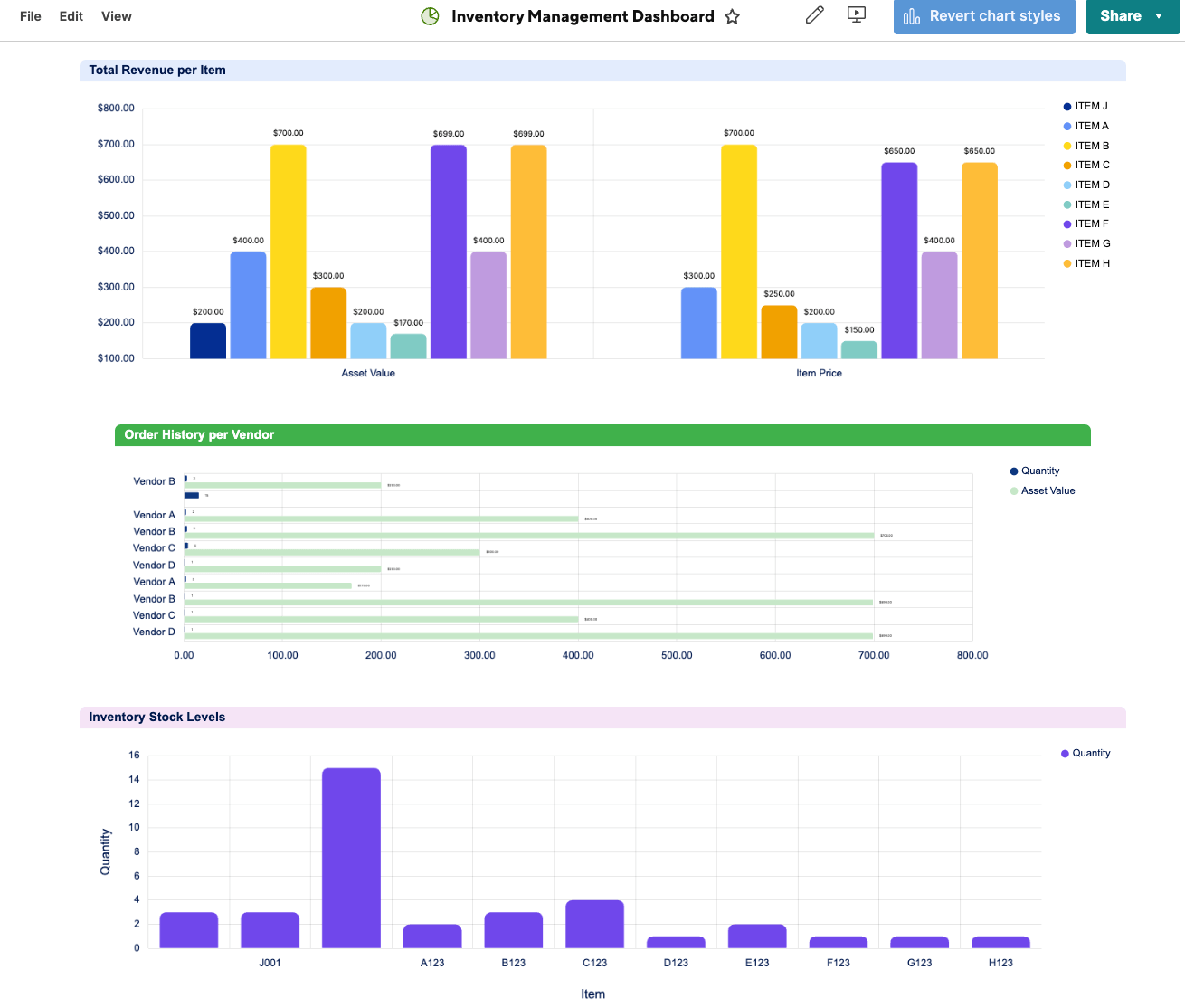

You can also get a quick view of stock status by viewing it on the corresponding inventory management dashboard.

Try Smartsheet Card View for Better Visibility Into Kanban Inventory Management

It’s easy for tasks to get lost in the madness of your everyday work. What you need is a better, more visual way to track and manage tasks.

Empower your team with board view in Smartsheet — a user-friendly task tracking solution that ensures seamless task prioritization, enhanced project visibility, and effortless agile collaboration.

Whether managing projects, optimizing workloads, or tracking to-dos, board view helps eliminate unnecessary status meetings by letting team members track project progress, completed tasks, and upcoming work with task cards.

Discover the intuitive drag-and-drop cards, real-time collaboration, and organizational card nesting that drive your organization to adapt and deliver more effectively.

Learn more about board view in Smartsheet.