History of Kanban

History of Kanban: Origins in Manufacturing

The terms of Lean, Kanban, and Lean Kanban have a lot of overlap (and also have a lot of interplay with the iterative software development methodologies grouped under the umbrella of Agile). They all share roots in Toyota’s “pull” methodology: Kanban was conceived as an inventory-control system for just-in-time manufacturing by an engineer named Taiichi Ohno at Toyota in the 1940s.

Ohno drew his inspiration from the way American grocery stores stocked their shelves, replenishing inventory when supply started to dwindle. Customers would purchase what they needed, and the store would reorder based on sales and forecasted demand. The stores only kept the amount on hand needed to meet customer demand.

Matching inventory to demand increased efficiency, reduced waste, and improved the quality of operations for grocers. This was a departure from systems based on top-down processes determined by management, using a fixed schedule or running inventory based on vendor priorities.

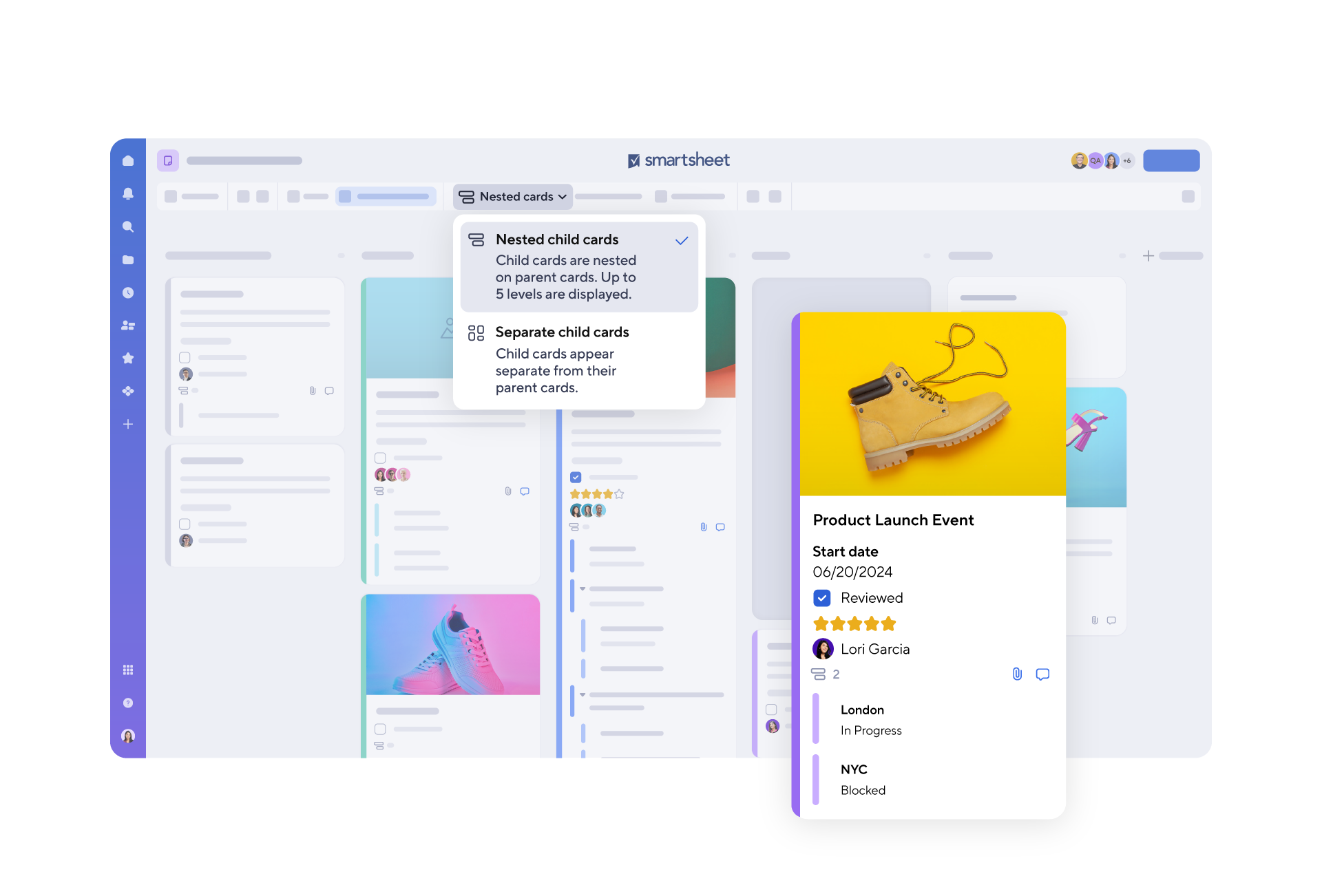

Prioritize and organize projects visually with Smartsheet Board View

Smartsheet offers a dynamic, visual approach to managing tasks and projects, making it easy to track progress, update statuses, and prioritize work in real time. With customizable Kanban-style lanes and drag-and-drop functionality, teams can stay organized, aligned, and focused on what matters most.

Explore the full range of robust features when you try Smartsheet free for 30 days.

Kanban Cards Are Visible Triggers for Production

Toyota took the grocery store practice and used it to improve its manufacturing system. Rather than work being pushed onto a team, work in Kanban was pulled in response to demand, similar to the way the grocery stores refilled shelves when they emptied. Kanban, pronounced KAHN-bahn, is a Japanese word that means sign, card, or billboard. At Toyota, assembly line workers used physical tokens as signals for just-in-time inventory replenishment and inventory control. These evolved into Kanban cards and today, they are usually printed bar codes attached to a physical object such as a tray or pallet. Toyota’s Kanban cards included Withdraw Kanban (which tells what kind and how many of an item should be taken from a prior process), Production Kanban (which tells the kind and quantity that the prior process should produce) and Transport Kanban (which signals when a full container of items should be sent downstream).

Let’s look at how a simple Kanban system works in manufacturing. One of the most basic examples is the Three Bin System. In this system, one bin of parts or supplies is on the factory floor, one is in the factory inventory, and one is at the supplier. When the bin on the factory floor is empty because all the components have been used in production, the bin is taken to inventory, triggering replenishment, and the empty bin is then sent to the supplier in exchange for a full bin. This system ensures there is always adequate supply - never too much or too little - with the third bin acting as a buffer absorbing any variances.

Kanban Helps Match Supply and Demand

Today, Toyota describes its method (which is part of its overarching Toyota Production System) as a “clear, sign-based scheduling system triggering the logistical chain of production and maintaining it at an optimal level.” Kanban is a quick-response system that harmonizes inventory with consumption.

Toyota has six rules for the effective application of Kanban:

Later process picks up the number of items indicated by the Kanban card at the earlier process.

Earlier process produces items in the quantity and sequence indicated by the Kanban.

No items are made or transported without a Kanban.

Always attach a Kanban to the goods.

Defective products are not sent on to the subsequent process.

Reducing the number of Kanban increases the sensitivity (meaning the fewer Kanban in your system makes it more sensitive to pull signals because there is less buffer between the processes .)

Lean Kanban Jumps to Software Development

Why Lean Kanban Succeeds in Divergent Industries

Lean, Kanban, Lean Kanban, and their Agile cousins have grown in popularity with information technology (IT) because they help businesses adapt, improve, and survive in the face of competition. This success has spurred interest from other service industries and even renewed interest among manufacturers and other traditional companies. Lean principles have also been embraced by many startup companies who feel the fast-feedback loop meshes well with a bootstrapped approach.

Anderson noted that Lean Kanban succeeds in the different domains of manufacturing and software for different reasons, but he cited two key similarities: in both manufacturing and services, this approach drives speed and provides rapid feedback. Both are great examples of Kanban’s focus on eliminating waste.

“In general, customers like faster delivery,” Anderson said. “It enables them to manage their own risks better and gives them more options. Opportunity cost of delay is avoided in many cases or commitment can be deferred against reliable, fast, and predictable delivery. Fast feedback has also been useful in physical goods environments. Customer tastes can change and being left with large quantities of unwanted finished goods is bad for business.”

Applying Kanban to intangible work such as software required adaptation. Shalloway, of Net Objectives, noted that Lean’s mantra to eliminate waste is much more visible in manufacturing (leftover materials, unused inventory, and defective products). In software, this waste is not as easily spotted, but often comes in the form of delays. These include time between getting requirements and using them, making an error and discovering it, and workflow interruptions or waiting for information. The Kanban board helps make bottlenecks visible.

Shalloway mentioned other ways that the analogues of Lean Kanban differ between manufacturing and software:

- Prototypes in the physical world work better because people can more easily imagine how they will interact with the product.

- In software, you can build incrementally without added cost (if you do it right) whereas in the physical world that is not always an available option.

- Designing interchangeable components in software is easier and cheaper than in the physical world.

- Automated testing is faster and more affordable in software than in the physical world.

Kanban was well established in physical goods industries such as manufacturing and distribution when people in the software world began to explore how Lean thinking could improve their work processes.

David J. Anderson, Chairman of LeanKanban, helped pioneer the adaptation of Kanban to knowledge work when he used Kanban systems as a process architect at Microsoft in the mid-2000s. He used Kanban at the heart of his method for driving continuous improvement within companies, a concept known as Kaizen in Japan.

Anderson chose to name his method after the Kanban systems that enabled it. In his book, Kanban - Successful Evolutionary Change for Your Technology Business, he described six key practices.

- Visualize your work

- Limit work in progress (WIP)

- Manage flow

- Make policies explicit

- Implement feedback loops

- Improve collaboratively, evolve experimentally

While Anderson’s practices are good guidelines, there is no universal agreement on the exact meanings of Kanban, Lean, and Lean Kanban in software development. Net Objectives’ Shalloway writes there are at least three distinct views of what Kanban represents: Kanban as a method to manage workflow (as popularized by Corey Ladas, author of Scrumban); Kanban as a subset of Lean thinking that should be used with other approaches (as Shalloway himself feels); and Lean Kanban as formulated by Anderson, which aims to help organizations transition to pull-based systems.

Kanban is now widely used in Agile software development and many non-IT businesses. Kanban is a highly flexible system because it focuses on starting where you are now, and therefore teams at any stage of production or efficiency can adopt the method. You can continue practices that are working well and make incremental changes when bottlenecks or problems are discovered.

In software, the visible signals of Kanban are created through a board with cards representing tasks or work to be done, called a Kanban board. The simplest board groups tasks under columns for To Do, Doing, and Done. The board can become more sophisticated with additional columns (testing, coding, etc.) and card types. Work limits are imposed for each category. A whiteboard can be used in Kanban, although online boards are pervasive these days because they can be updated instantly and shared by teams in multiple locations.

Only when a task has been moved from “Doing” to “Done” does capacity open up for a team member to pull a new task from the “To Do” column. This is how the pull-based system from Toyota’s production line evolved for knowledge work.

Anderson says that in some ways, Lean Kanban’s success in service fields was surprising since the work is largely invisible (as opposed to the highly physical work of factories). “It is counterintuitive that techniques which work by limiting inventory and signalling just-in-time replenishment would be useful for professional services but they are,” he said.

“To leverage this you need a way to measure and represent inventory,” Anderson said. “It turns out that a service request is a good unit for inventory in professional services….If you are managing an IT department, you might process requests for system installations or designs for new features in application. These are service requests and you must treat them as units of inventory to enable a Kanban system.”

Lean Kanban in Manufacturing Today

There are powerful examples of Lean Kanban’s success in manufacturing today, but the methodology is still struggling to reach critical mass outside Japan, experts say. Gary Conner, a Senior Consultant at the Oregon Manufacturing Extension Project who advises companies on Lean transformation, has seen the dramatic improvements that Lean can make. For example. FCC Commercial Furniture, an Oregon maker of furniture for major fast-food chains, saw the time it takes to manufacture furnishings for one restaurant outlet drop from one week to 55 minutes after moving to Lean.

Luis Ramirez, Chief Operating Officer of Florida-based contract manufacturer MC Assembly, said that in the year since embracing Lean, his company has cut in half the the set-up time for its surface-mount printed circuit board assembly and achieved a 60 percent increase in the number of production lines it is able to kit. (This refers to gathering all the components needed for a particular product at point of use.)

For manufacturers who implement Lean Kanban, “The greatest benefit is much less inventory and freeing up money for other core company needs,” said Chuck Intrieri, Senior Principal Consultant of The Lean Supply Chain.

Proponents agree that despite its origins in manufacturing, Lean and Lean Kanban continue to struggle to gain traction in production facilities outside Japan. By their estimates, only five to 20 percent of U.S. manufacturers are seriously pursuing this approach.

Tony DeCaria, a Continuous Improvement Strategy Manager at Detroit-based utility DTE Energy, said that Lean Kanban adoption is hindered by a lack of commitment by leadership at most companies and a reluctance to dedicate the time and energy to develop a Lean culture.

“Usually it fizzles out before it works,” said DeCaria. “A lot of people don’t understand it and they focus on the tools, not on the philosophies.”

As a result, “forward-thinking Lean manufacturers are putting their focus on people development and developing the in-house know-how of how to improve. Particularly in regards to cost reduction, the know-how of how to improve becomes a powerful competitive tool in poor economic times,” said Ben Sparrow, a consultant with Australia’s Shinka Management, which focuses on spreading Lean manufacturing practices and training manufacturers in Toyota’s techniques.

Sparrow predicted Lean will continue to face an uphill path and added, “The West will continue to evolve its own understanding of Lean that will unfortunately lead to more failures than successes. In Japan, there are countless success stories spanning decades of Lean being applied to organizations both inside and outside of manufacturing. I think we need to push aside those language and cultural barriers, and seek further engagement with Japan to extract the keys to a successful and sustainable lean organisation.”

Create a Custom Kanban Board with Smartsheet and Share it with Your Team

It’s easy for tasks to get lost in the madness of your everyday work. What you need is a better, more visual way to track and manage tasks.

Empower your team with board view in Smartsheet — a user-friendly task tracking solution that ensures seamless task prioritization, enhanced project visibility, and effortless agile collaboration.

Whether managing projects, optimizing workloads, or tracking to-dos, board view helps eliminate unnecessary status meetings by letting team members track project progress, completed tasks, and upcoming work with task cards.

Discover the intuitive drag-and-drop cards, real-time collaboration, and organizational card nesting that drive your organization to adapt and deliver more effectively.

Learn more about board view in Smartsheet.