What Is a Construction Schedule?

A construction schedule is a construction project’s master timeline. It explains when work starts and finishes, how the tasks flow in order, and where milestones fall. The schedule gives managers and crews a shared roadmap that shows what’s next, and it helps forecast when the project will be complete.

Summary Overview

|

What to Include in a Construction Schedule?

A construction schedule should cover the full work scope — this includes a work breakdown structure, a resource plan, dates and deadlines, dependencies and durations, milestones, procurement steps, inspections, and risk buffers. With resources, calendars, and a baseline in place, the schedule is ready for action.

Use these elements to formulate your construction schedule:

- Work Breakdown Structure (WBS): Split up your construction project into doable work packages and activities. For more, see our guide on construction work breakdown structure.

- Dependencies and Logic: Show how tasks interconnect to the ones before it and after it, using standard relationships such as finish-to-start or start-to-start. Be sure to use project and crew shift calendars that match real working hours.

- Durations with Basis: Use production rates, vendor quotes, or past data to support time estimates.

- Resource Plan: Note what labor, equipment, and material is required for your project, and decide how the resources will be allocated over time. Resources can be leveled, meaning the project schedule is slowed down to prevent overallocation (adjusting the schedule to fit the resources), or they can be smoothed, meaning that certain tasks in the schedule might be frontloaded to prevent project delays (adjusting the resources to fit the schedule).

- Milestones: Include major events in the construction project lifecycle. This might include every stage from the project kickoff to the completion of the foundation, structural framing, and interiors; permit approvals and financing draws; and owner decision points, before the final project handover.

- Procurement and Inspections: Make sure the schedule leaves room for material deliveries that require lead time or product approvals that might take time. Schedule official code inspections to prevent project delays.

- Risk Allowances: Factor in uncertainties such as weather, site access, resource and equipment availability, economic factors, supply chain delays, or seasonal restrictions with dedicated buffers or calendar adjustments.

- Baseline and Updates: Use your original approved schedule as a baseline, then define how often you’ll make updates and adjustments to the schedule. You can make updates at specific milestones or at regular intervals.

- Coding and Filters: Add identifiers to every activity in the schedule. They can be sorted by discipline (e.g. structural, electrical, plumbing), location within the structure, or budget line item so that you can sort and report easily.

- Quality Checks: Run schedule assessments to confirm clean logic, realistic float, and reliable dates. For example, the DCMA 14-point check was originally developed for defense contracts, but is now widely used in construction to test schedule quality.

Learn how to choose the right construction scheduling software to help you run automated quality checks.

Combined, these elements form a solid construction schedule, a core tool in both construction planning and construction project management.

How to Create a Construction Schedule

Creating a construction schedule starts with compiling plans, budgets, and vendor details to build an activity list. Select a schedule tool that manages calendars, task logic, and dependencies. Then create and refine your draft schedule, and update it regularly as the project progresses.

The following are the five main steps to creating a dependable construction schedule:

Gather Project Information

To create an accurate construction schedule, you need to know and understand every aspect of the project. This requires a thorough review of the design specifications, budget, subcontractors, zoning rules and building codes, bill of materials, and procurement plans. By creating a work breakdown structure (WBS), you can organize the process and ensure that you capture the right scope.

Select a Project Management Tool

A variety of available construction-specific applications and software make scheduling easier. Spreadsheets in Excel or Google Sheets might suit smaller projects, while complex jobs require critical path method (CPM) tools that handle dependencies, calendars, baselines, and reporting. On many public or large-owner projects, these may be required. Choose software that participants can use comfortably, with communication features and templates to support collaboration.

Create a Draft Schedule

Incorporate work dependencies into your initial draft schedule. Leave buffers for uncertainties and common sticking points, such as code inspections. Consider any seasonal or site factors that might slow progress. This helps ensure your proposed construction schedule is realistic before it’s shown to the client or stakeholders.

Tip: Adam Mopsick, CEO of Amicon, which specializes in construction management and owner’s representation, says buffers will depend in part on the type of project and local conditions. Ask yourself whether the open date for this particular building is flexible or how long building permits take to acquire in this specific location. The best way to determine buffers is to review past projects with similar specifications.

Refine the Schedule and Set the Baseline

Share the draft schedule with stakeholders and make sure that it’s realistic and viable. Document all communications for later reference, and include the procurement and lead times of all tasks in the work breakdown structure and Gantt chart. Note any project milestones that affect the release of funds. Once finalized and approved, the schedule should be set as the baseline. Measure future updates against it.

Maintain Open Lines of Communication

Your schedule and Gantt chart will evolve as the construction project progresses. Keep the schedule up to date. Even if delays occur, you may be able to prevent them from impacting the project completion date by reallocating resources or adjusting other phases in the schedule. Weekly sessions with short look-ahead plans are especially useful for spotting issues before they affect the critical path.

Tip: Mopsick recommends holding regular meetings with project participants and agreeing upon means of communication. Updates can be sent via email or notifications in the project management tool. Whatever the method, it is important that everyone knows how they will receive information.

Step | Tip | Pitfall |

|---|---|---|

| Gather project information | Collect all project details — plans, permit requirements and review times, vendor lead times, and site conditions — so the schedule reflects reality. | Relying on incomplete information can cause missed permits or material delays that push back the whole job. |

| Select a scheduling tool | Choose a tool that most people already know of and is easy to use. | If you choose a complex tool, people might avoid using it, increasing the risk of schedule inaccuracies. |

| Draft a schedule | Add buffers to tasks that are prone to delays. | If task links or the critical path are wrong, the finish date will be unreliable. |

| Consult stakeholders | Make sure to get input from subcontractors. | Failure to check the draft schedule with project participants might result in last-minute problems that are difficult to resolve. |

| Refine and finalize schedule | Acquire and document all approvals for the schedule. | Failing to secure approvals or record the basis for the schedule can cause disputes later in the project. |

| Update as you progress | Hold regular meetings to exchange information. | Poor communication can lead to disputes. |

How to Create a Construction Schedule in Excel

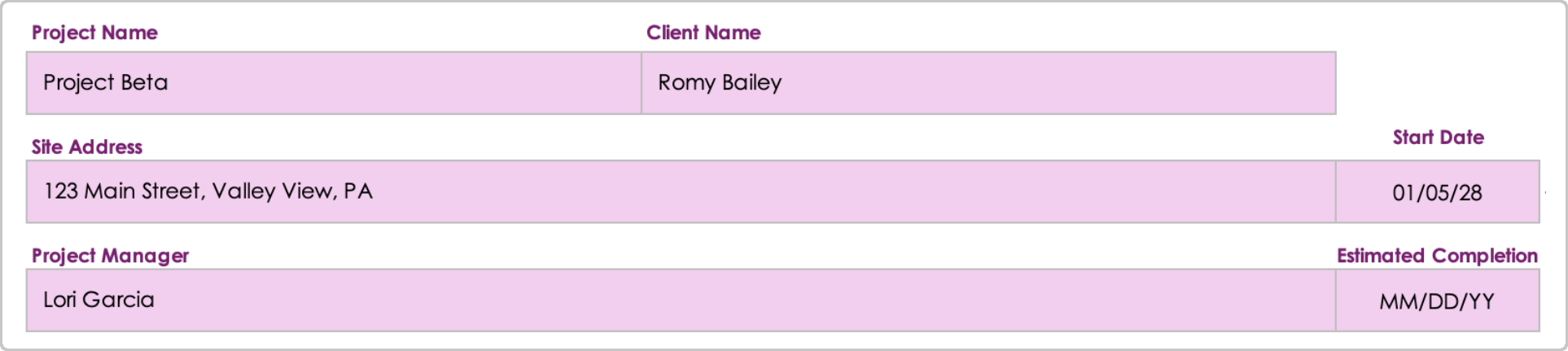

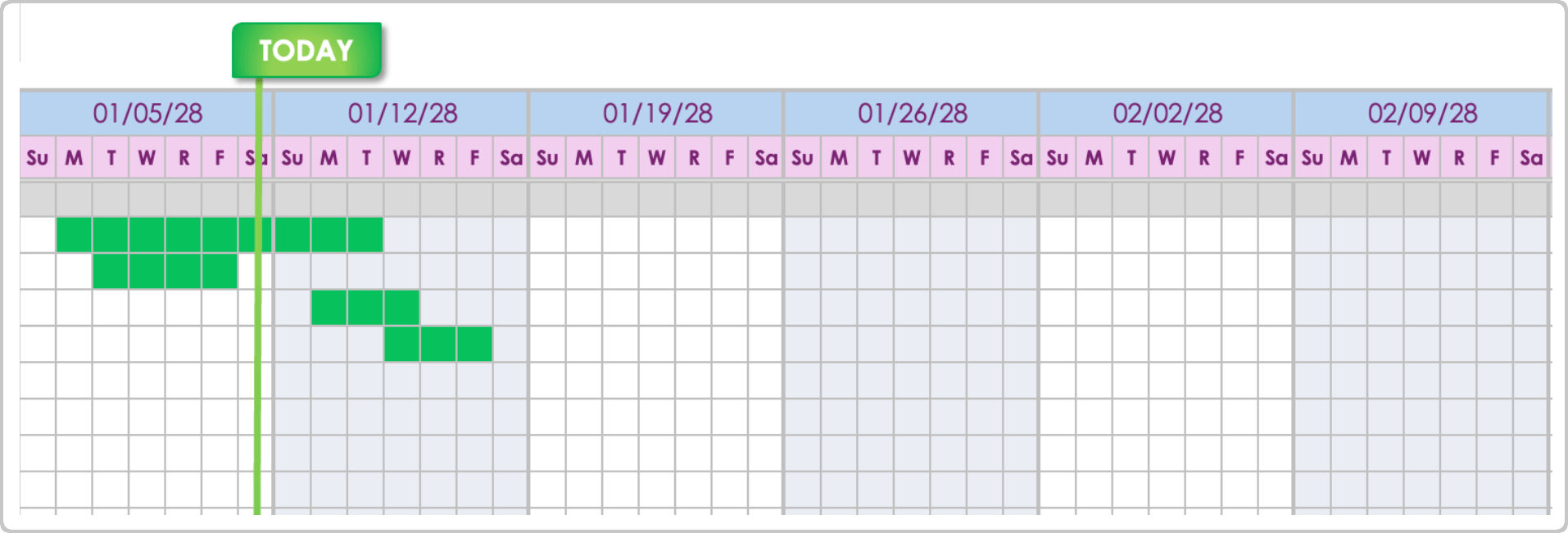

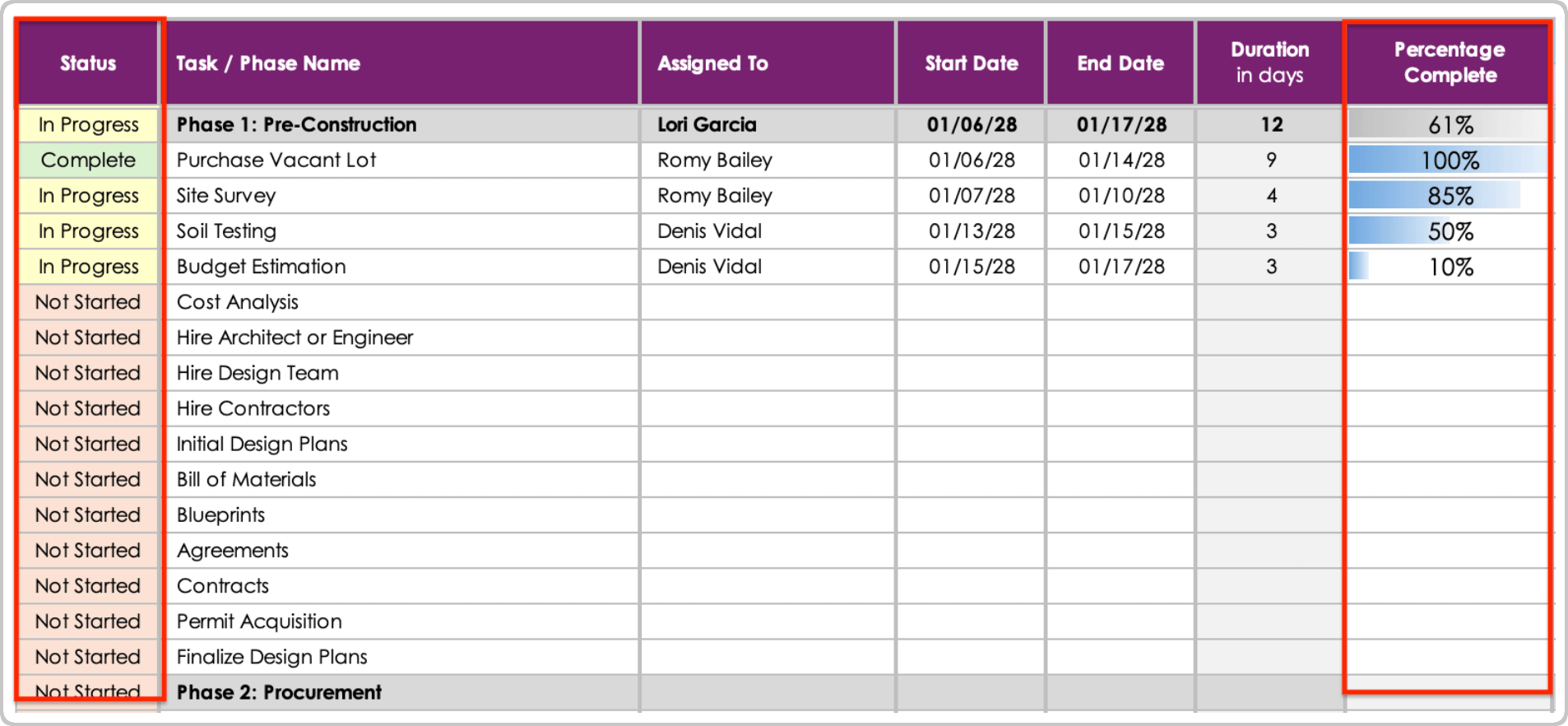

To create a construction schedule in Excel, use the template provided and fill in project details, responsible parties, and relevant dates. Assign start and end dates for each task, and update its status as the project progresses. Use the Gantt chart to create a visual timeline of your project.

Here are the steps to creating a construction schedule in Excel:

- Download and open the residential construction schedule template for Excel .

- Fill in the Project Name, Client Name, Project Manager, and Site Address fields for your project. Enter the start date of construction (the first Sunday in your project timeline) and your estimated completion date.

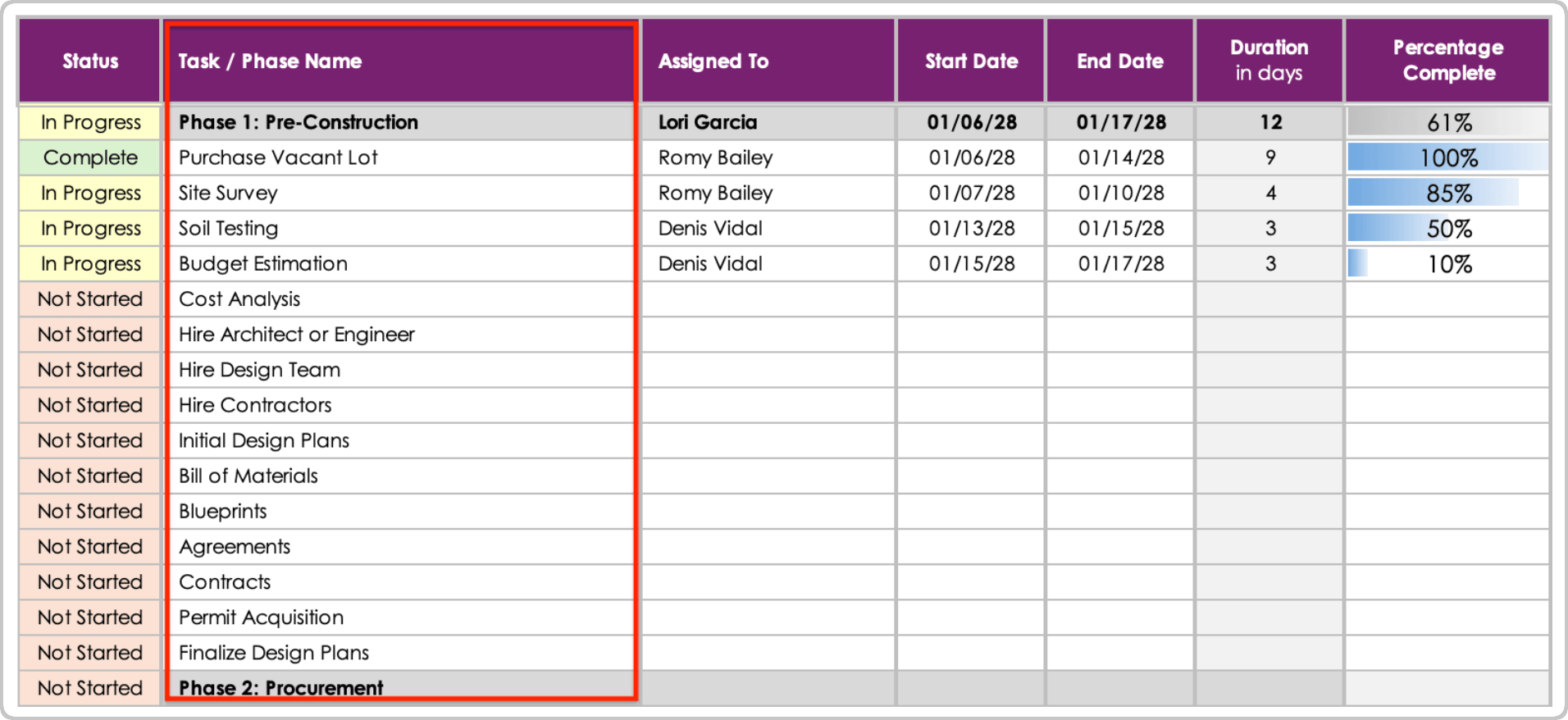

- Identify all the tasks in each phase of your project and add a line for each task. These tasks are organized by phase.

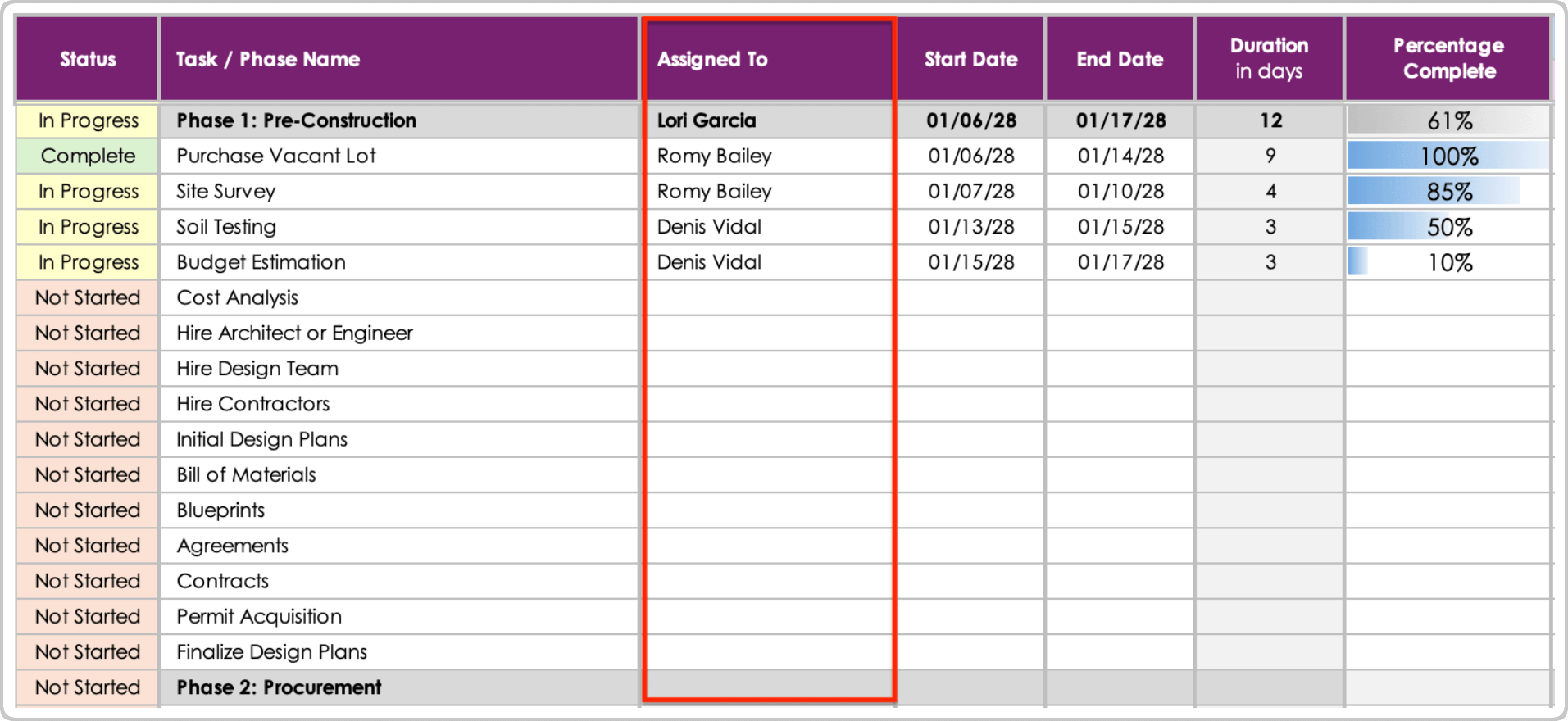

- In the Assigned To column, enter the name of the person who will be held accountable for each task.

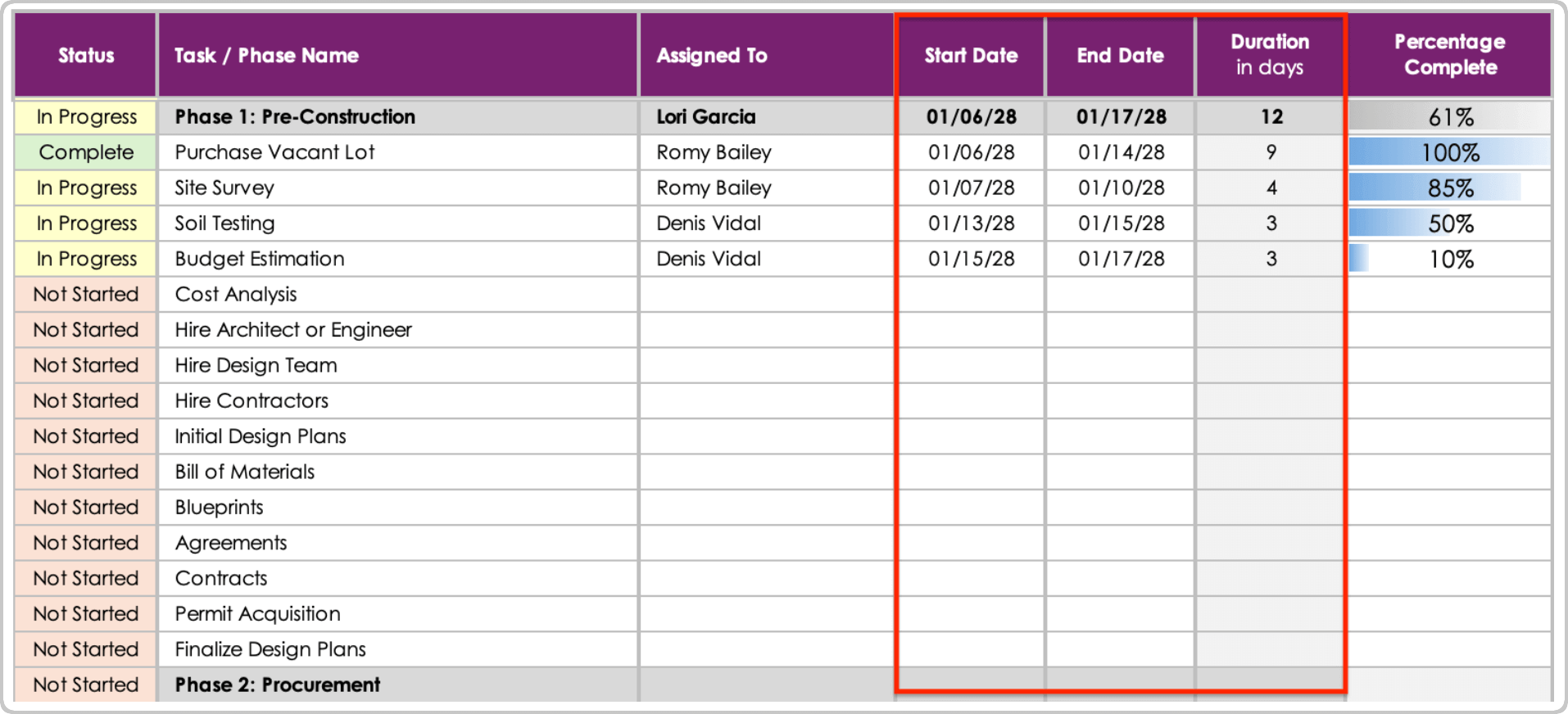

- Fill in the estimated start and end dates for each task. The duration of the task will be calculated automatically.

- Fill in the days estimated for each task into the Gantt chart to have a visual timeline of your overall project from start to finish.

- For each task, use the drop-down menu in the first column to update the status of completion in real time. Select from Not Started, In Progress, and Complete. Use the Percentage Complete column to note the completion percentage. The cells will automatically shade to reflect that value.

Try one of these other construction management templates to suit your project requirements.

Construction Scheduling Methods

The construction scheduling method you select depends on project size, complexity, and risk. These methods include the critical path method (CPM), the program evaluation and review technique (PERT), resource scheduling, and quantitative scheduling.

A single-family home project might require a basic Gantt chart, while you might use Lean approaches such as the Last Planner System for complex builds with many trades.

Review the following methods to see which approach might best suit the needs of your project or team:

- Critical Path Method (CPM): Estimate the total completion time of a construction project by identifying all dependent tasks in your timeline. These are tasks that a team cannot begin until another task is complete. When using the critical path method, managers can anticipate changes to the completion date when any activities in the critical path happen earlier or later than planned.

Learn more about how to use the critical path method for construction.

- Program Evaluation and Review Technique (PERT): Estimate the completion date of a construction project by factoring in optimistic, pessimistic, and most likely schedule forecasts. Managers start with a diagram of a building project, then use the PERT formula to weigh the most likely time estimate more heavily than the other two. This method reflects potential for the project to vary and is more sensitive to risk, which makes it especially helpful for one-of-a-kind or novel construction projects.

Find templates and learn more about applying PERT to your projects with our full guide to PERT.

- Gantt Chart: Build a simple spreadsheet that lists each task needed to complete a project and tracks their progress over time. This document, called a Gantt chart, allows you to update future activities and completion dates based on actual progress. Construction managers like Gantt charts because they allow for a quick, high-level assessment of overall progress and make it easy to spot problems and delays.

Learn more about using Gantt charts and find how-to videos with our Gantt chart guide. Also see our construction Gantt chart templates.

- Line of Balance (LOB): Track actual progress against anticipated progress with a line-of-balance chart. This method is best for construction projects that involve repeated units of work, such as tall, multifloor buildings that require the same tasks for each floor. Using this method, managers can chart how long each repetition takes and predict the time needed to complete the remaining units. This method also helps managers adjust schedule forecasts as a team completes repeated tasks more quickly. This technique has limited value in projecting total duration of the critical path because it only takes into account the repeated tasks.

- Quantitative Scheduling: Schedule the use of materials and equipment at different locations in the most efficient way using the quantitative method. Also called Q scheduling or queue scheduling, this technique focuses on how the order of activities and the allocation of resources impact budget. This is a visual method that displays the quantity and duration of resources needed at different project locations at various times.

- Resource Scheduling: Prioritize efficient allocation of resources while also factoring in time, labor, funding, space constraints, and other important project details. There are two primary ways of dealing with resource constraints: Resource leveling allocates resources at a consistent level and adjusts the project schedule as a result. For example, rather than the crew working overtime, you would schedule workers for 40 hours every week and add weeks to the project. Resource smoothing, in contrast, prioritizes time constraints. In this case, you would either change project activities so that resource need does not exceed capacity or add more resources.

Find more tips and tools with our guide to resource scheduling.

- Last Planner System: Use a holistic Lean approach that accounts for all the moving parts of a construction project. A trademarked approach, Last Planner System divides projects into five stages of planning. Master planning involves building a construction schedule for the entire project. During phase planning, managers make detailed schedules for each project phase, whereas in weekly work planning, they make schedules that can be completed reliably each week. The make-ready and learning phases help managers anticipate constraints and reflect on areas of improvement as a project progresses.

To learn more about the Last Planner System and other Lean techniques, see our guide to Lean project management.

- Look-Ahead Planning: Prepare a project schedule that covers a short upcoming period, usually six weeks or fewer. As part of the make-ready phase of the Last Planner System, construction managers use a look-ahead schedule to prepare for upcoming work. This process is usually incorporated into a weekly work plan.

Types of Construction Schedules

Construction schedules can take different forms depending on how much detail they include and how managers intend to use them. Common types are the master schedule for overall planning, milestone charts to track key events, and a baseline schedule that locks in the approved project timeline.

These schedules are applied across all sectors — residential, commercial, industrial, and infrastructure — with the level of detail and the person maintaining the schedule varying by project type.

Here’s how each type works:

- Master Schedule: Compile all high-level scheduling details for a construction project into a master schedule. This comprehensive, easy-to-read document specifies the major deliverables, individual work breakdown structure elements, and milestones for an entire project. Also called a level one, management, integrated master, or major milestone schedule, the master schedule is usually one page, includes a Gantt chart, and incorporates information from all aspects of the project.

- Milestone Chart: Summarize the major milestones of a construction project in a simple chart. Milestones are key events, deliverables, and important dates, rather than tasks or activities. Typical major milestones on a building project include permit approval, contract award, punch list, and final walkthrough.

Learn more about the construction punch list, including tips and templates.

- Schedule Baseline: Finalize and obtain approvals for a project schedule at inception that shows the targeted timeline for construction. By doing so, managers can have a basis of comparison for the actual progress that makes it clear when work is behind schedule. The baseline schedule does not update as the project progresses.

Find free construction schedule templates, including residential and two-week schedules, in our comprehensive collection.

What Makes a Good Construction Schedule?

A good construction schedule is complete, realistic, and flexible. It covers all work, sequences tasks with accurate durations, reflects collaboration and communication, and provides control and protection to keep projects on track and within budget.

Key qualities of a good schedule include the following:

- Completeness: It covers the full scope of work with tasks, milestones, and dependencies.

- Accuracy: A good schedule is realistic and uses accurate durations and resource inputs confirmed by subcontractors and suppliers.

- Flexibility: It adapts to weather delays, inspection changes, material shortages, or client-driven revisions.

- Collaboration: Input from managers, subcontractors, and field crews ensure that a construction schedule is feasible.

- Control: An effective construction schedule sets an approved baseline and is updated regularly with actual progress and logic changes.

- Protection: It reduces disputes, keeps cash flow predictable, and safeguards contractors from penalties or claims.

Tips for Good Construction Scheduling

Strong construction schedules reflect the full scope of work, realistic durations, and potentially disruptive risks. Managers should monitor lead times, collect up-to-date data, consider unusual or unpredictable elements in a project, and thoroughly understand their project context in order to build effective schedules that keep projects on track.

We’ve gathered advice from experts to help you prepare a construction schedule and avoid common pitfalls:

- Consider Full Scope of Work: A schedule that only covers actual construction tasks will fail to capture the real timeline.

Jim Brucato, President of Principle Construction Corp., says it’s essential to factor in pre-construction activities such as site acquisition, procurement, financing, and permitting.

Clients may also have scheduling constraints that managers need to consider. If, for example, the building owner is leasing an alternative location and must vacate on a certain date, that restriction might dictate certain design and material choices.

“These factors can shape a project,” Brucato says. “Start by making sure you understand the overall project.”

- Monitor Lead Times: Material availability remains one of the biggest variables in scheduling. Shortages can be caused by global or economic factors and can cause long wait times for key equipment such as HVAC systems, switchgear, and specialty finishes. A single late delivery can stall inspections, delay dependent work, and push back project completion.

- Collect Data Diligently: Seek updated price, availability, and lead time quotes from vendors for every material in your project. Subcontractors should also go through this process, so your schedule is based on current conditions.

“Be extremely proactive,” Mopsick advises. “Take nothing for granted. Make a phone call for every line item in the budget.”

Similarly, check task duration estimates and work sequencing with all participants in the construction process. This can expose problems early and help you avoid major complications down the road. Keep good records of past projects, so you can use that information as a basis for scheduling similar activities.

Centralized construction management software makes it easier to track vendor data, past project records, and updated lead times.

- Factor in Uncertainties: A project might involve nonstandard elements that can be tricky to schedule. Avoid roadblocks by identifying these elements early on and factoring potential delays into the schedule.

Examples include unusual site conditions, such as building on wetland that requires environmental review; or a public-private financing model, where the timing of approvals or funding is uncertain.

“These can be very fluid and can derail your schedule,” Brucato says.

On the other hand, the timing for tasks such as installing drywall can be easily predicted and act as a standard reference to back up estimates.

- Know the Region: Local factors, such as weather, building codes, permit review processes, labor availability, other construction underway, union contracts, and wage trends, all influence the schedule of a construction project.

As your portfolio grows, you will gain expertise on factoring local conditions into your schedules. For example, Mopsick’s company, Amicon, is active in South Florida, so his team knows how to handle scheduling around hurricane season.

Streamline Your Construction Projects With Smartsheet for Construction

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Construction Schedule FAQs

A construction job schedule is the short-range plan that organizes day-to-day work on site. It shows what crews, equipment, and materials are needed in the coming days or weeks. This site-level schedule connects the overall project plan to actual production.

Construction schedules vary by project type and location. A typical schedule for an American single-family home is around 10 months from permit to completion, according to census data. Commercial and infrastructure projects often run longer because they involve more complex permitting, financing, and procurement requirements.

The critical path method (CPM) is the most widely used approach in construction. You can use it to map dependencies between tasks, calculate float, and identify the longest sequence of activities that determines project duration. Owners and public agencies frequently require CPM schedules on large or complex projects.

The general contractor is usually responsible for creating and maintaining the construction schedule. Subcontractors and suppliers provide input on task durations and sequencing. Owners and architects often review the schedule, but the contractor controls updates and ensures the plan reflects field conditions.

A construction schedule provides the framework for managing time, cost, and resources. It helps teams coordinate work, plan procurement, and anticipate risks. Without a schedule, projects are more likely to suffer from delays, cost overruns, and disputes over responsibilities and deadlines.