What Is a Punch List in Construction?

A punch list is a checklist of work that still needs finishing or fixing before a construction project can be deemed complete. This process ensures outstanding issues are documented and resolved before final payment.

Summary Overview:

|

The punch list might also be called a snag list, deficiency list, or punch-out list. Contracts often mandate it at substantial completion, the stage that allows the owner to move in or use the space while contractors finish remaining tasks. Owners might hold back a portion of payment, called retainage — typically five to 10 percent — until every item is resolved.

Punch lists are meant for small or moderate corrections. Minor imperfections that still meet contract standards might be considered reasonable flaws, while more serious errors are unreasonable flaws that must be corrected. Larger changes or new requests usually result in a change order, rather than a punch list item.

Typical punch list items include the following:

- Small Finish Repairs: This might include paint touch-ups or surface scratches.

- Minor Installation Issues: Doors that don’t latch or uneven flooring are installation issues that might be on a punch list.

- Functional Items: These include plumbing leaks or switches that don’t work.

- Damage: Damage that occurred during construction needs to be fixed, such as broken glass or cracked tiles.

- Missing Paperwork: This includes warranties or as-builts, which are drawings showing how a building was constructed rather than designed.

The fixes are called punch-out work, which includes all final action items that need to be completed before the project officially ends. Punch-out work is usually the final stage of a construction project. The punch list, vital to any project’s successful completion, serves as a core tool of construction project management.

When Are Punch Lists Created?

Traditionally, a punch list is created near a project’s end during substantial completion. However, they can also be created at phased turnovers, on a rolling basis, or during commissioning. Many contractors now use a zero punch list approach, which addresses issues throughout construction to ensure fewer last-minute fixes.

These modern strategies stress prevention. For example, rolling lists fix line items by trade or area as work progresses. This avoids a massive backlog before final turnover. How punch lists are timed often depends on the project scale.

Here are a few different timing methods for punch lists:

- Phased Turnovers: On large-scale projects such as hospitals, multiple-building complexes, and industrial plants, separate lists are made for areas that are completed. For each area that’s finished early and turned over to the owner, the contractor prepares a separate punch list.

- Rolling Lists: Issues are tracked by trade or location throughout construction, cutting down on the number of issues that need to be checked at closeout. This approach is used in both residential and commercial projects.

- Commissioning: Primarily in complex commercial, industrial, or health facilities, punch items for mechanical/electrical/plumbing (MEP) systems arise during formal functional testing (commissioning). This happens long before the final architectural walkthrough.

A proactive approach is key for large-scale projects, says David Case, Founder and President of Advastar. He provides owner’s representation and staffing support to clients in construction, energy, and manufacturing.

“This means creating initial punch lists during prefunctional checks and system commissioning,” Case explains. “Then it’s a matter of updating them as equipment comes online and narrowing the list when we’re approaching final completion. Doing it this way avoids having a massive punch list at the end, which I’ve seen delay turnover.”

For single-family homes and other less complex projects, a punch list is still commonly prepared near the end. However, more builders and tradespeople are adopting proactive approaches. Some pursue a zero punch list philosophy of continuous quality control, emphasizing stage inspections and self-checks to prevent defects. Both zero punch lists and rolling lists aim to deliver a cleaner closeout with fewer disputes.

Whatever your specific punch list timing, it’s best to define your approach during construction project planning.

Items Typically on Punch Lists

Punch lists usually cover a range of small but important items, grouped into categories that address finishes, installations, equipment, safety and code, and documentation. Items might look minor, but the fixes ensure the project fully meets the contract before closeout.

Typical categories are the same through the different construction types, but specific line items will vary:

- Finishes and Surfaces: These might be paint touch-ups, wall patching, improperly sealed building expansion joints, or repairing cracked paving.

- Installations: Installations might include misaligned ceiling grid tiles, improperly installed commercial door hardware, doors that don’t close properly, or incomplete roofing/flashing details.

- Equipment: HVAC systems might need balancing, the fire alarm panel might show trouble signals, electrical panels might be mislabeled, or light fixtures might not be functioning.

- Safety/Code Items: These include missing exit signs, inadequate fire-stopping, incorrect ADA-compliant signage, or missing guardrails.

- Documentation: As-built drawings, warranties, owner instructions must be complete and up-to-date.

By addressing these items, contractors demonstrate that the work is truly complete, while owners gain confidence that the project has been delivered as promised.

The most common items vary by trade or type of project.

Andrew Bates, COO of Bates Electric, handles a range of residential and commercial projects. “The most common punch list items we find largely revolve around functionality and safety, such as outlets or switches that are not functioning properly, lights that do not appropriately illuminate the space, or electrical panels that do not pass code,” he says. “Occasionally, we are required to punch-list items that are more cosmetic in nature, such as exposed wires or poorly positioned fixtures.”

David Case says he sees a few recurring themes in large-scale projects his company handles.

“Safety-related issues are the most frequent. These are often small details, like missing signage or trip hazards, that are easy to overlook in earlier stages. Functionality issues are also common — for instance, if controls aren’t tuned, equipment isn’t calibrated properly, or system tie-ins are incomplete.”

While these are more critical categories, Case adds, “there will also often be more cosmetic finish quality issues with alignment, paint, sealants, etc., as well as documentation gaps that need to be addressed before turnover.”

If you are in construction or quality assurance, discover which applications are considered the best punch list software for mobile reporting and real-time updates.

The Construction Punch List Process

A construction punch list is first drafted by a contractor, then the team walks the project to add items. Next, a master punch list is compiled, responsibilities are assigned, and corrections are made and verified before closeout. The process might be done in a rolling or phased approach.

Here are the steps to creating and completing a punch list:

- Conduct a Pre-Punch Review

Tradespeople and foremen walk their areas and correct small issues, such as chipped paint or loose door hardware, before the formal walkthrough.

Pro Tip: Have each subcontractor submit a pre-punch self-check before the GC walkthrough — it saves time and reduces duplicate items.

- Walk Through the Project Together

The contractor, owner, and design team walk the site to identify issues. For instance, an owner might note a scratched cabinet, or the designer might see missing handles.

Pro Tip: Bring blue tape and mark every issue on-site during the walkthrough to avoid missed or forgotten items later.

- Compile a Master Punch List

The contractor consolidates all items into one record, often in a construction management software with notes, photographs, and marked-up plans.

Pro Tip: Use a cloud-based punch list tool so that everybody can see updates in real time instead of getting mired in multiple spreadsheets.

- Assign Items

Every item is assigned to the appropriate subcontractor or trade with deadlines.

Pro Tip: Record the responsible trade and due date for every line item — it lessens confusion.

- Make Corrections

Subcontractors resolve their items, such as fixing drywall, stopping leaks, or replacing damaged tiles.

Pro Tip: Require each subcontractor to upload photo evidence of corrections — it speeds up verification and lessens repeat inspections.

- Verify the Fixes

The contractor or design professional inspects corrected items and designates them as resolved. If you’re not using software, you can go with these punch list templates for tracking.

Pro Tip: Employ a simple status system — for example, items can be labeled as Open, In Progress, Verified, or Closed — to keep the verification process straightforward.

- Close Out the Project

Once all items and documents are complete, retainage is released and the project is declared finished.

Pro Tip: Tie retainage release directly to punch list completion so that everyone has a financial incentive to close items quickly.

How Process Timing Varies by Project Type

A structured process, whether simple or phased, helps teams in any construction sector finish strong, cut down disputes, and deliver a project both owners and contractors can sign off on with confidence.

The sectors break down as follows:

- Residential: Punch lists often happen once, near move-in, with owners providing many of the observations. However, more and more contractors and subcontractors are using a rolling approach.

- Commercial: Construction teams might implement rolling punch lists by floor, tenant space, or system to keep closeout manageable.

- Infrastructure: Agencies set strict deficiency-list procedures tied to turnover milestones (e.g., road sections opening to traffic).

- Industrial: Punch list timing overlaps with commissioning; systems testing often leads to punch list items months before project turnover.

Construction Punch List Roles

Several participants share responsibility for punch lists. The owner identifies issues, the general contractor coordinates the list, subcontractors carry out the corrections, and architects or designers confirm it all meets specifications. On larger projects, additional specialists might also contribute.

Here are some core participants who work on punch lists:

- Owner: The owner inspects completed work, adds items during walkthroughs, and confirms that the project meets expectations.

- General Contractor (GC): The GC prepares and manages the punch list, assigns items to subcontractors, and ensures the necessary corrections.

- Subcontractors: Subcontractors fix their assigned items and give updates or documentation once the work is complete.

- Architects and Designers: Design professionals verify that the finished work meets contract specifications, join walkthroughs, and might add items for correction.

“A project manager leads the punch list, but there is value in allowing the lead designer to lead as well,” says Josh Qian, the COO and Co-Founder of LINQ Kitchen. “Having someone approach the list who is also looking at aesthetic components of the project is valuable, as any project will have both technical and aesthetic elements that need to be addressed.”

Additional roles on larger-scale projects can include the following:

- Construction Manager/Owner’s Representative: A CM or representative coordinates the punch list process on behalf of the owner, tracks closeout, and enforces accountability.

- Commissioning Agent: Commissioning agents raise and verify system-specific items during testing of HVAC, electrical, or process equipment.

- Quality Control Staff: Quality assurance and quality control staff provide formal inspections, document deficiencies, and confirm that corrective actions have been taken.

- Maintenance Staff: Facility teams might participate in walkthroughs to flag operational concerns before handover.

These additional roles are more common on large commercial, infrastructure, or industrial projects where the complexity of systems and scale of work require specialized oversight. On smaller residential projects, the punch list participants might be only the owner, the builder, and a few trades.

“We control and facilitate our punch list items,” says Andrew Bates, whose company handles residential and commercial projects. “However, we coordinate with the general contractor and client to get all items handled properly. The general contractor will supervise the general punch list process and the client's final sign-off.”

“The general contractor should manage the punch list, but it only works if the owner and subcontractors are actively engaged,” emphasizes Brian Curran, a structural engineer and founder of Drafting Services LLC. “Owners bring the user perspective, while subcontractors know what’s feasible within their trade. In practice, the GC needs to act as coordinator, setting deadlines and ensuring accountability.”

The roles might move around for some larger-scale construction projects, although the coordination is similar.

“Our approach is that the GC or EPC contractor should take the lead in managing the punch list, but the owner’s representative provides critical oversight,” says Case. “I find that the collaboration is smoothest when the GC maintains a centralized punch list system that everyone can access; then subcontractors are responsible for executing fixes; and the owner’s rep verifies that items aren’t just checked off, but have been adequately addressed.”

Get a handle on all aspects of your project with construction management templates.

How to Improve the Construction Punch List Process

You can improve the construction punch list process by encouraging each trade to catch internal issues early and use clear acceptance criteria. Implement checks on a rolling basis and hold regular reviews to ensure accountability. Use digital tools to help coordinate corrections and verify fixes.

Improvement starts before the final walkthrough. By engaging trades in self-checking, defining what “done” looks like, and using tech for capture and tracking, teams often prevent punch list item overload. Below are steps you can adopt to tighten up the punch list process.

Try these steps to improve your punch list process:

- Encourage Trade Self-Inspection: Encourage each trade to review their scopes (e.g., finishing, MEP, installations) multiple times during construction, catching issues such as flooring gaps or misaligned hardware early.

“We support a zero punch list approach,” says Andrew Bates. “That is why we implement deep quality controls throughout the whole project — not just at punch-out. The foreman walks through after every stage looking for anything wrong as they go and then immediately addresses anything they find.”

- Define Clear Acceptance Criteria: Use mock-ups, walkthrough checklists, or contract standards so that everyone knows what “finished” means — for example, what qualifies as acceptable paint finish, what tolerances for alignment, and what mechanical performance levels.

- Use Digital Tools: Digital punch list software allows teams to create a visual record. Some contractors use 3D modeling to catch problems early and move closer to a zero punch outcome.

“An effective approach is using digital punch list tools that let the GC photograph, tag, and assign issues in real time,” Curran says. “Its visual record eliminates disputes about what was requested and when.”

“Using technology applications like 3D modeling and connected jobsite data, we scan the layout before we even speed up the production,” Bates says. “This is to make sure we get as close as possible to a zero-punch situation, which ultimately benefits everyone. In the end, it saves time and money.”

- Implement Rolling Checks: Rather than waiting, perform punch walks by area, floor, or system before final completion. For instance, finish the first few floors or systems fully before moving on. This can smooth out trade overlap and bottlenecks.

Michael Benoit, founder of California Contractor Bond & Insurance Services, advises using punch lists for ongoing quality control.

“After each walkthrough with an owner or architect, I update the punch list in writing and make sure each responsible party sees the revisions,” says Benoit. “I have used this process on projects as large as $25 million, and it has helped avoid disputes on responsibility for missed items and protected the retention payments.”

- Run Tests Early: For complex mechanical, electrical, or plumbing systems, run tests and identify issues early. Fold the results into a punch list regularly. This avoids leaving system-level defects until closeout.

- Hold Regular Review Meetings: Set up frequent check-ins between the owner, GC, trades, and design team to review outstanding punch items. Make sure responsibility and deadlines are clearly assigned so that items don’t linger.

“Establishing a clear timeline for resolving punch list items, with accountability for each party, significantly reduces end-of-project delays,” says Qian.

- Tie Punch Lists to Payments: Treat the punch list as more than a checklist — use it as documented proof that the project meets contractual requirements before releasing retainage. Closing the list only after every item is verified protects cash flow, shortens the time to payment, and reassures all parties involved.

“At final completion, I close the punch list only after every item has been resolved and verified by the owner’s representative,” Benoit says. “This timing matters because it provides documented proof that the project meets contractual requirements and it triggers final payment and release of retainage. On a million-dollar contract that retainage can be five to 10 percent, which means between $50,000 and $100,000 is tied to the punch list.”

Layering in these strategies moves teams closer to the goal of a zero punch list and smoother project delivery.

Zero Punch List Readiness Checklist

Want to hand over projects with no lingering punch list items? This free zero punch list readiness checklist shows you how to build in quality from day one with trade self-checks, rolling reviews, and stage inspections.

Download the Zero Punch List Readiness Checklist for Adobe PDF

Inspection Tips for Owners

When conducting a final walkthrough, bring your contract to compare to finished work. Inspect the project slowly and thoroughly, test functionality, and mark any issues with blue tape. Take photos, videos, and notes. It might also help to bring someone along for a second set of eyes.

Here are some tips for conducting a thorough final walkthrough:

- Bring Plans and Specifications: Keep a copy of the contract documents handy so you can compare the finished work to what was agreed.

- Take Your Time: Don’t rush. Inspect each room, paying attention to both installations and details such as paint, trim, and finishes.

- Test Functionality: Open and close every door and window, run faucets, flush toilets, switch on lights, and operate appliances.

- Check Work in Different Conditions: Look at finishes in natural and artificial light, and listen for squeaks, rattles, or HVAC noise when the building is quiet.

- Use Blue Tape: Mark every issue you see with tape so that it stands out for the contractor and crews.

- Document with Photos or Video: Shoot pictures or short clips of issues to create a record and avoid disagreements later.

- Bring a Friend: A second set of eyes helps ensure you don’t miss anything.

- Take Notes: Record each issue with enough detail to guide repairs and keep for your own records.

- Verify Documentation: See if you’ve received all required as-built drawings, O&M manuals, and warranties, and confirm that what was installed is correct.

These practices apply to all types of projects, though the focus changes with complexity. In residential construction, owners often rely on blue tape and photos during the final walkthrough. In commercial and institutional projects, owners’ representatives or facility staff join inspections and emphasize system functionality and documentation. For infrastructure and industrial projects, inspections focus on commissioning results, safety compliance, and operational readiness.

Common Punch List Challenges

Punch lists can stall closeout if they grow too long, lack clear ownership, or capture the wrong types of items. Common punch list challenges include confusion over responsibilities, scope creep, gaps or overlaps in work or documentation, or disputes about quality.

Even well-run projects face obstacles when closing out. Minor defects can balloon into delays if they aren’t documented clearly, assigned properly, or resolved quickly.

Below are some frequent challenges with punch lists, along with practical ways to overcome them:

- Unclear Responsibility: When it is not obvious who owns a correction, items linger unresolved. Avoid this by assigning every punch list entry to a specific subcontractor or trade with a deadline, and require photo or written proof of completion before verification.

“If the owner, GC, and subcontractors are working off of different lists, that can lead to inefficiency, rework, or things falling through the cracks,” Case notes. “Tying closeout items to payment milestones can help with the accountability aspect and prevent subs from delaying fixes.”

- Scope Creep: Owners or teams sometimes add new requests that go beyond the original contract. Prevent disputes by clarifying that new scope must be handled through a change order, not added to the punch list, and set that expectation at project kickoff.

“The biggest challenge I see is when the punch list becomes more of a wish list,” Curran says. “I’ve seen owners try to add new work under the cover of punch items. The solution is clear documentation, and defining what’s a deficiency versus what’s a change order.”

- Overloaded Lists: Saving all inspections until closeout can create hundreds of items and weeks of extra work. Use rolling punch lists or phased turnovers to spread out inspections and minimize last-minute backlog.

Try to avoid “an overload at the end, where there are hundreds of open items at substantial completion,” says Case. “This can be fixed with early punch list tracking during commissioning and a turnover that’s phased by area or system.”

Bates also notes the overload challenge. “Coordinating all of the various subcontractors and controlling who is responsible can be difficult to manage. Bates Electrical has begun using punch list software digitally, and it has allowed us to assign tasks and control our work in real time. This avoids the last-minute push at the end of the project.”

- Overlapping Work: Punch list corrections sometimes interfere with other finished work, causing delays or damage. This is especially tricky when multiple trades are working in the same area during closeout.

“One challenge is sequencing fixes without disrupting completed work,” Curran says. “A late flooring repair, for instance, can set back cabinetry or painting that was already finished. My strategy is to group punch items by trade and zone, then schedule them like mini work packages, so they don’t overlap destructively.”

- Disputes Over Quality Standards: Without clear acceptance criteria, teams might disagree over what counts as complete. Establish benchmarks early with mockups, specifications, or inspection checklists to set expectations.

- Documentation Gaps: Missing warranties, as-builts, or operations and maintenance (O&M) manuals can delay payment just as much as physical defects. Track these deliverables alongside punch list items to keep closeout on schedule.

- System-Level Issues: For complex projects, functional problems in HVAC, plumbing, or electrical systems might surface late. Align commissioning with punch list creation so that system tests identify and resolve problems before turnover.

- Occupied Spaces During Closeout: When owners begin moving in before completion, crews often struggle to access areas or schedule corrections. Coordinate with occupants early and sequence punch list work to reduce disruption.

- Communication Gaps: If punch items are tracked across multiple emails, spreadsheets, or notepads, issues get duplicated or missed. Use a centralized platform with real-time updates to make sure everyone is working from the same list.

Most punch list challenges come down to clarity, accountability, and timing — the same factors that determine whether closeout is quick or painful.

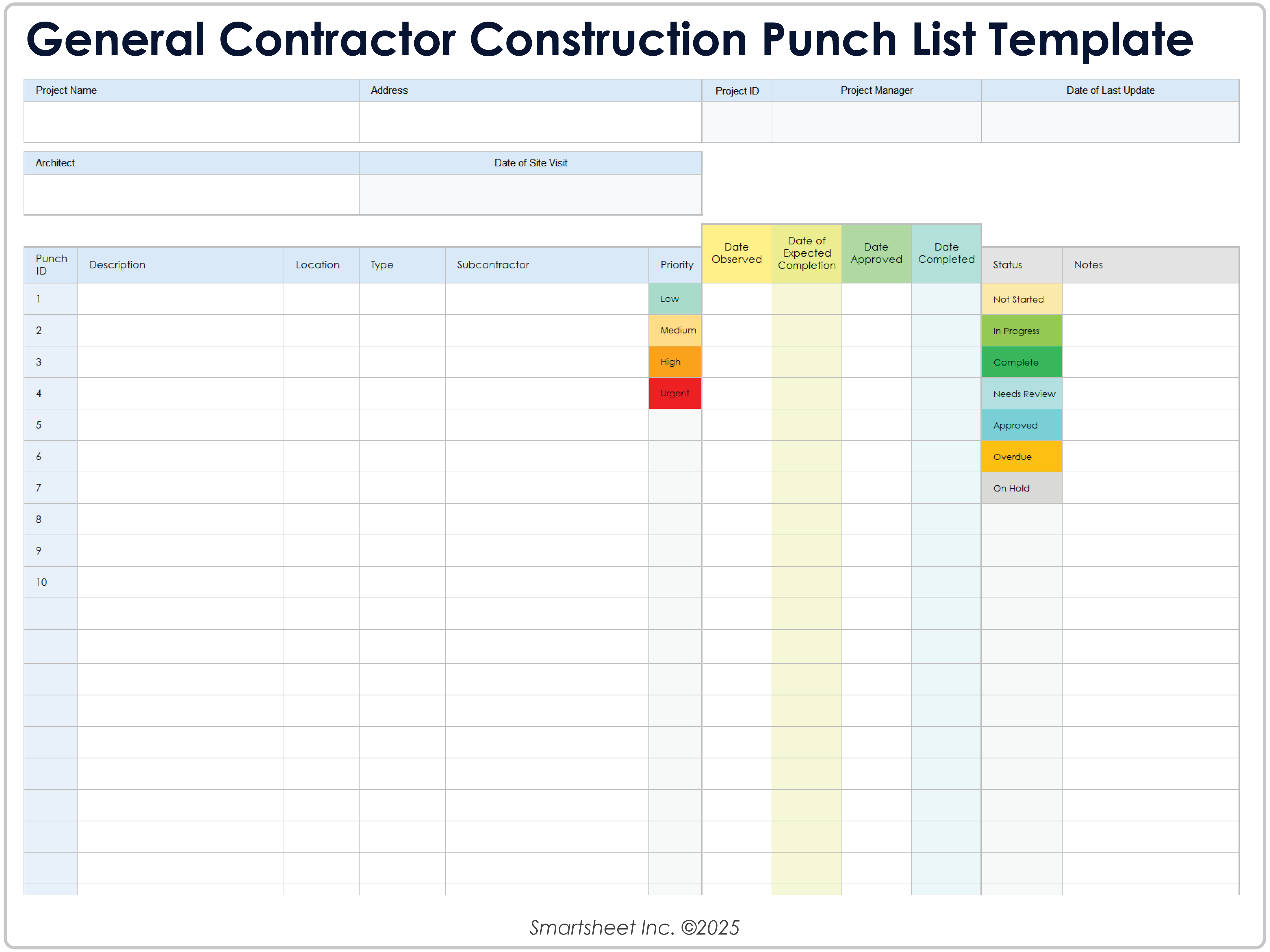

Construction Punch List Template

Use this general contractor construction punch list template to manage approvals and sign-offs for a project with multiple roles. It allows the project manager to track each task to completion, and each task can be organized by subcontractor type or priority level.

Download a General Contractor Construction Punch List Template for

Excel

|

Microsoft Word

| Google Sheets | Google Docs

For more options, see these construction punchlist templates.

Streamline Your Construction Project From Start to Finish With Smartsheet

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Construction Punch List FAQs

A punch list may also be called a snag list, deficiency list, punch-out list, or completion list. Different terms are used across regions and contract types, but all describe a record of work that must be corrected or finished before project closeout and final payment.

Try this collection of construction snag list templates to get started.

Punch lists are used in nearly all construction projects — residential, commercial, industrial, and infrastructure — as a way to capture and resolve deficiencies before closeout. They might be less formal on very small jobs, but on larger projects they are a contractual requirement.

A punch list is not a separate contract, but it is enforceable under the construction agreement. Owners might withhold retainage or final payment until listed items are resolved, and contractors remain responsible for delivering all contract work even if an item was omitted.

To create an effective punch list, keep it clear, specific, and organized. Include a location, description, responsible party, and deadline for each item. Add photos or plan markups to reduce disputes. Track progress in one system and get verification before closeout — this ensures accountability and quality.

The best punch list software for construction supports mobile capture, photos, plan markups, trade assignments, and real-time updates. Smartsheet offers customizable templates, automated workflows, dashboards, and photo/image attachments, which make it useful for both residential and commercial punch list workflows.