What Is a Construction Cost Overrun?

A construction cost overrun is when construction project expenses exceed the budget. It occurs when the actual spending becomes higher than the planned spending, increasing the total project cost. Cost overruns can be the result of several factors, including poor estimates or unexpected costs, shortages, or delays.

Summary Overview

|

Common Causes of Construction Cost Overruns

Construction cost overruns can be caused by preventable factors, such as poor planning and communication, inaccurate estimates, or design errors. They can also be caused by unexpected issues such as scope creep, change orders, or price fluctuations, as well as external factors such as supply chain disruptions.

Here are some common reasons for construction cost overruns:

- Poor Planning and Communication: To ensure that your construction budget stays on track, have systems and processes in place to keep all stakeholders updated and aligned. Maintain thorough document management and accounting, make sure all workers have the skills to facilitate effective communication, and establish a single source of truth for all teams.

Duncan Cartlidge, a chartered surveyor and author of the Construction Project Manager’s Pocket Book, explains that inadequate risk analysis and poor risk allocation can result in optimism bias. “That’s assuming everything will go according to plan, which it seldom does,” he says. “Perform rigorous risk assessment and allocate risks to those most able to manage the risk, even if that means paying a premium.”

- Poor Estimates: Inaccurate cost estimates can happen when planners overlook site conditions or underestimate labor or material costs. External factors such as regulatory changes or inflation can also result in poor estimates. To avoid this, assign skilled and dedicated experts to planning the budget and inspecting the site, and make sure all stakeholders are aligned on the process early on.

Improve your estimates with this step-by-step guide to construction cost estimating, and get started with these construction estimate templates. Considering software to help you plan? Don't miss our roundup of best construction management software options.

- Poor Resource Allocation: Poor resource allocation can involve materials, labor, or time — for example, having too much or too little of a certain material available at the wrong phase of a project, assigning the wrong workers at the wrong time, or misjudging how much time a certain task will take to complete. Improper allocation can lead to issues, such as excess or shortage of material, idle or overworked staff, or wasted or overburdened equipment, which can create inefficiencies or delays.

Check out this complete guide to resource allocation to learn more.

- Design Errors: Design errors include incorrect measurements or dimensions, unclear drawings, unrealistic structural plans, or noncompliance. If designs have to be reworked, this can cause delays and unexpected cost increases, as well as disrupt the project momentum.

- Scope Creep: Scope creep is when a project’s requirements, features, or deliverables expand beyond the original project plan. Scope creep can be caused by various factors, including late-stage client demands, unclear planning, or poor change control processes. Without a clear change management system, projects can become overly complex, leading to delays, cost increases, poor quality, or resource strain.

Read this guide to understand the causes of scope creep, how to identify it, and how to mitigate it. You can also try one of these free construction scope of work templates to get started.

- Missed Hidden Costs: It’s easy to overlook hidden costs in your initial budget. These can include administrative or regulatory costs, such as inspections, permit fees, licenses, jurisdictional fees, or changing industry requirements. They can also be costs caused by poor training, ineffective use of technology, quality control failure, or environmental factors, such as decay. These costs can emerge in the middle of a project, disrupting your budget or requiring contingency funds.

- Change Orders: Change orders are formal modifications to the original contract. They involve changes to the design, materials, or schedule of a project. Some of these modifications might be unavoidable, but too many of them can increase costs significantly. They can cause workflow disruptions, wastage, or require extra labor or materials. These inefficiencies can delay a project and cause overruns.

This guide to construction change orders offers tips and best practices for maximizing project success, and this collection of construction change order templates can help you get started.

- External Factors: Environmental or economic factors such as site conditions, weather and climate change, supply chain disruptions, trade regulations, global pandemics or wars, inflation and price fluctuation, or labor and materials shortages can be difficult to predict. As they change, costs can increase, which can lead to overruns.

Construction Cost Overrun Cause and Solutions

Cause | Solution |

|---|---|

| Poor cost estimates that underestimate actual requirements | Independent or third-party estimators to validate bids before approval |

| Design errors or incomplete drawings that require costly fixes later | Early design audits, peer reviews, software checks, and building information modeling before construction begins |

| Scope creep when the project expands without the proper authorization | A scope statement or scope baseline to help you maintain focus, and a formal review board to approve or reject scope changes with cost/impact analysis |

| Change orders during construction that inflate costs | Change order protocols such as official sign-offs and cost breakdowns to reduce the number of change orders in a project |

| Poor communication and misaligned expectations that cause delays and rework | A centralized platform or collaboration tool for transparent sharing of updates, documents, and approvals |

| Environmental factors, such as site conditions, weather, or regulation changes | Contingency funds, mitigation plans, and documentation of real-time risks to assign owners and response strategies in advance |

| Economic factors, such as price fluctuations, tariffs, or supply chain disruptions | Escalation clauses, sourcing material from different regions, hedging against commodity price changes, locking in prices early, and monitoring economic trends |

Learn more in this complete guide to construction project management, which includes budgeting, scheduling, and risk management tips.

How to Prevent Cost Overruns

Cost overruns can be prevented or minimized through detailed planning, contingency funds, real-time cost tracking, collaboration software, and accurate reporting. Teams can also reduce their impact after they occur by revising budgets, renegotiating with vendors, reallocating resources, delaying noncritical features, and freezing spending in overrun areas.

Jason Schroeder is the founder of Elevate Construction and creator of a popular YouTube channel for aspiring construction project managers. In one of his video tutorials, he emphasizes the importance of preventing cost overruns not just by cutting costs but by adding value. “You cannot manage by subtraction,” he says. “You have to buy and pay for the things that you need to make sure the project goes right … it costs money to plan.”

Learn more about construction cost management and best practices, and go further with these construction management templates.

Here are a few more tips for preventing cost overruns:

- Have a Detailed Plan: The best way to prevent a cost overrun is to plan thoroughly before executing a construction project. Involve highly trained professionals when planning your budget and create a detailed risk management plan. Use the scope as a reference point to prevent scope creep.

Don’t be afraid to allocate spending up front. Wherever possible, it’s better to spend on known factors that add value to a project, rather than allocate excessive funds to a contingency. Have multiple sign-offs on your plan so that all stakeholders are on the same page and you can more reliably catch potential issues. “Factor in market volatilities, such as funding costs and skill shortages,” Cartlidge adds.

- Track and Report Costs: Real-time cost tracking and reporting give project teams immediate visibility into spending against their budget. This allows them to spot deviations early and adjust timelines or reallocate resources as needed. Smartsheet tracks estimated costs alongside actual expenditures in customizable templates, reports, and dashboards that pull live data from project sheets and automatically calculate variances. After data capture and monitoring, teams can analyze trends and accurately forecast costs to prevent overruns.

- Maintain Vendor Relationships: Clear and open communication with vendors ensures high-quality support, favorable contracts, and possibly competitive pricing or bulk discounts. Vendors might honor contracts in a situation of market fluctuation or provide warnings in advance of shortages or price hikes. “Ensure early engagement with tier-two or tier-three supply chain members,” advises Cartlidge.

- Have a Contingency Fund: A contingency fund is a safety net for expenses that arise in the middle of a project that aren’t in the original budget. The contingency fund can be drawn on for unexpected costs, such as price fluctuations, site conditions, economic factors, or design changes. A contingency fund won’t prevent unforeseen costs, but it can absorb them. This ensures that these costs don’t exceed the original budget and cause an overrun.

Choose from this collection of construction budget templates.

- Use Collaboration Software: Collaboration software centralizes all communication, automates workflows, and ensures effective document management. It keeps all stakeholders aligned on goals, timelines, and budgets, and ensures that everyone is aware of updates or adjustments, such as design changes or approvals. It also encourages accountability by clarifying responsibility for each risk. These features help prevent delays or wastage, which can in turn minimize the risk of overruns.

Streamline all phases of the construction project lifecycle with the right construction management software.

- Use Real-Time Reporting: Real-time insight into budget performance helps teams avoid overruns by tracking actual costs against estimates and making quick adjustments. Teams can reallocate resources or adjust timelines to prevent overruns and larger-scale budget issues. Tools such as Smartsheet provide automated workflows, integrations, and dashboards to help you plan, schedule, and document your construction project from pre-construction through delivery.

Get tips and best practices for creating a construction work breakdown schedule with this guide.

Tips to Prevent a Cost Overrun | Corrective Action if That Fails |

|---|---|

| Set a realistic budget with 5–10 percent set aside for your contingency fund. | Revise the budget to create a new baseline and reset expectations with stakeholders. |

| Vet vendors and lock in contracts early to reduce the risk of unreliable suppliers or price swings. | Renegotiate with or switch your vendors, or arrange phased deliveries to regain cost control. |

| Use forecasting tools such as BIM to improve upfront estimates and reduce guesswork. | Use variance analysis to identify where estimates went wrong and adjust resource allocation. |

| Define scope and change management protocols clearly to prevent scope creep. | Defer scope elements and remove or delay noncritical features. |

| Establish regular monitoring and reporting practice to catch small deviations before they grow. | Freeze spending in overrun areas, reallocate contingency funds, and increase reporting. |

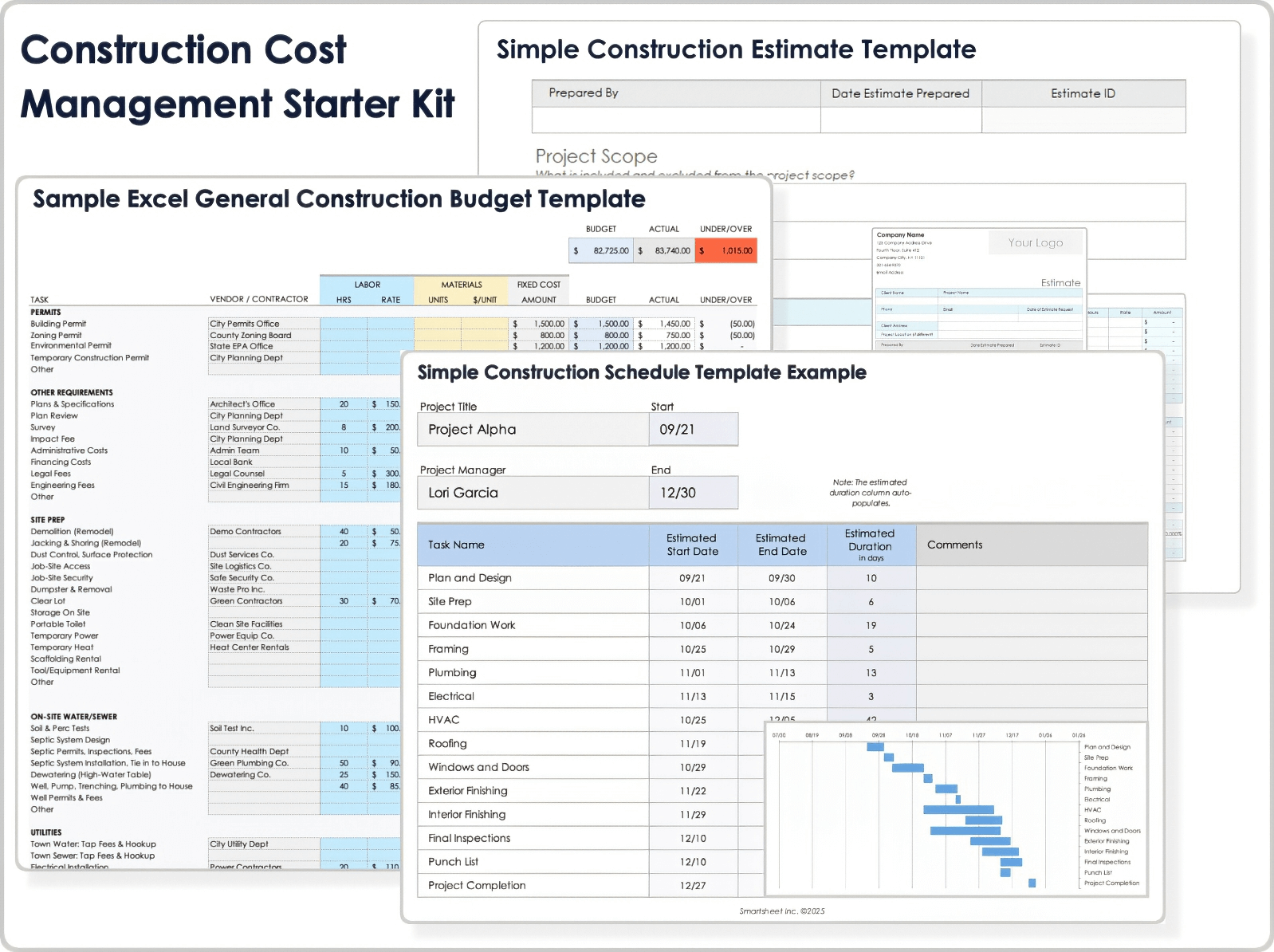

Construction Cost Management Starter Kit

Download the Construction Cost Management Starter Kit

Use this starter kit to help you plan and maintain construction costs and avoid overruns. It includes a cost estimator and a budget template.

In this starter kit, you’ll find:

- A construction schedule template for Excel to help you visualize your project from start to finish

- A construction budget template for Excel to help you monitor and adjust your budget throughout the project

- A construction estimator template for Excel to create accurate and effective cost estimates alongside supporting documentation

How to Use AI to Minimize Overruns

AI helps minimize construction cost overruns by analyzing project data to predict risks, optimize resources, and improve estimates. Tools such as predictive analytics, AI-powered estimation, procurement optimization, and real-time monitoring allow teams to forecast budget issues early. When integrated into workflows, AI supports smarter decision-making.

According to a 2024 study in the International Journal of Communication Networks and Information Security, by using predictive analytics, machine learning, and computer vision, AI can “facilitate cost estimation accuracy and reduce risks, allocate resources more efficiently, and improve decision-making processes. AI-driven models analyze past data to predict possible budget problems so that managers can manage cost related risks in an online or proactive way. AI case studies show cost overrun reduction across projects worldwide.”

The following chart shows some of the specific AI features and tools that can help you avoid construction cost overruns. Each tool or feature works by analyzing relevant data to generate trends and insights, but project teams still need to select the right tool and configure it properly. Make sure you integrate your AI tools into a structured workflow.

AI Tool/Feature | How It Prevents Cost Overruns |

|---|---|

| Predictive analytics for budgeting | Improves risk management by forecasting potential overruns and delays from historical and real-time data, allowing action to be taken before financial problems escalate |

| AI-powered cost estimation | Analyzes market conditions and material prices to make cost projections, reducing the risk of underbudgeting and unexpected expenses |

| Automation of routine accounting tasks such as invoice processing or change orders | Saves time, prevents human errors, and keeps financial records accurate, lowering the chance of unnoticed overspending |

| Smart resource management | Adjusts schedules and reallocates resources based on availability and constraints; reduces wastage or inefficiencies that inflate costs |

| AI-driven procurement optimization | Secures cost-effective deals, bulk purchase strategies, and supplier selection through analysis of market data, lowering material costs and avoiding procurement delays |

| Predictive risk assessment | Spots material shortages or design conflicts before breaking ground by analyzing historical and market data; models scenarios (e.g., digital twins) to optimize resources and minimize unexpected costs midproject |

| Real-time resource optimization | Tracks and improves equipment, labor, and delivery; boosts productivity through better scheduling; cuts material waste; and minimizes idle time costs |

| Proactive maintenance | Extends equipment lifespan, predicts equipment failure, lowers unplanned downtime, and reduces maintenance expenses by avoiding costly emergency repairs |

| Enhanced collaboration and decision-making | Reduces communication delays, ensures all teams are working from the same project data, improves supplier coordination, and increases stakeholder confidence |

How Smartsheet Helps You Avoid Cost Overruns

Smartsheet helps construction teams avoid cost overruns by providing real-time project visibility, automated workflows, and centralized collaboration that streamline decision-making, track budgets, and improve overall project control.

Here are the ways Smartsheet can help you avoid construction cost overruns:

- Real-Time Tracking: Smartsheet enables teams to monitor project progress, resource allocation, and budget performance using dashboards and roll-up reports. Real-time data access ensures that all stakeholders are on the same page about project status and any sudden changes in timeline, workflow, or budget.

- Automated Workflows: Automated workflows in Smartsheet help to minimize manual errors and ensure consistency. Automatic notifications can be set up to alert teams to budget updates or upcoming deadlines so that they can avoid costly delays.

- Centralized Visibility: By centralizing project documentation, schedules, and communication in one platform, Smartsheet reduces miscommunication and ensures everyone works from the most up-to-date information. This improves transparency and prevents scope creep, unapproved change orders, and missed hidden costs.

- Integrated Budget and Resource Management: Built-in tools help you manage budgets, track expenses, and predict future costs, so you can keep a close eye on a project’s financial health. Resource management features help optimize allocation to prevent over- or underutilization.

- Streamlined Change Management: Smartsheet supports change order tracking and approval workflows, ensuring that any modifications are properly accounted for in the budget. This reduces the likelihood of unplanned expenditures that derail project finances.

Compare the best construction budgeting software to find the best solution for your team.

Drive Intelligent Work Management for Construction Projects With Smartsheet for Construction

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Construction Cost Overruns FAQs

A cost overrun is when a project’s actual expenses exceed its planned or budgeted expenses. A budget deviation refers more broadly to any situation where actual expenses differ from the budget. A deviation can be a cost overrun or an underrun.

Cost overruns impact a project by causing financial strain, exhausting budget, and reducing profit margins. Efforts to control overruns can also force poor quality, reduced scope, or delays. This in turn can strain the organization as a whole by damaging reputation and stakeholder trust and limiting future business opportunities.

A construction project budget should include anywhere from five to 15 percent of the estimated total cost of the project. The exact figure depends on the size and complexity of the project, the level of risk involved, the specific industry or market conditions, and the level of experience of the team.

Learn how to calculate your contingency and create a contingency budget plan with this guide.