What Is a Construction Submittal?

In its general usage, the word submittal functions as a synonym for submission, meaning something that you submit for consideration or a decision by others. However, in the context of construction, submittal has a more specific meaning: A construction submittal consists of shop drawings, samples, production specifications, technical data, and other written and/or physical information that help architects and engineers make sure that the correct items are installed in new buildings. Construction submittals can even include soil samples.

Usually, one uses construction submittals only for complex projects. For the most part, the plans or a finish schedule will specify what materials you’re going to use for simple buildings (such as houses), and the architect and builder will handle any discussion concerning these items.

On big projects, the submittal process is well defined and formal. The contract and project specifications for larger-scale construction will require the contractor to turn in construction submittals to the architect and engineer for approval before proceeding. Frequently, especially on large projects, the contractor will direct subcontractors to prepare the submittals for their specialties.

Objectives of the Construction Submittal Process

Submittals play a crucial role in the building process, as they help ensure the following:

- Building systems, such as elevators and ventilation, have the right utility connections and structural support.

- Pre-fabricated items are ordered correctly.

- Working conditions are safe for construction personnel.

- The completed structure matches the design and specifications set by architects and engineers.

- The building is safe for its occupants and its intended use.

- The project succeeds in meeting its cost, quality, and schedule objectives.

Failure to carefully follow the construction submittal process can have disastrous consequences.

A dramatic example of this kind of failure was the 1981 collapse of two walkways suspended above the lobby of the Hyatt Regency Hotel in Kansas City. The accident killed 144 people and injured 216. At the time, it was the worst structural collapse in U.S. history.

Investigators found that the design of the steel tie rods was responsible. The manufacturer proposed a design change to the project engineer over the phone, and the engineer approved it orally without performing calculations to ensure it would bear the load adequately. A state judge found the structural engineers guilty of gross negligence, and they lost their professional licenses. Settlements in lawsuits brought by victims totaled about $63 million, more than it cost to build the hotel. In this case, rigorously following the submittal process could have saved many lives.

How Are Construction Submittals Used?

As we have discussed, submittals are the primary way that architects and engineers verify that you are using the correct building materials. Many times, designers do not select finish materials before they complete construction drawings. So, the submittal process is an opportunity for architects to confirm colors, patterns, and types of materials. They do not make any design changes, but clarify what they want within the specifications shown on the plan.

For building components that require fabrication (such as structural steel), the architect and engineer review details from the manufacturer (those that the contractor selects) to make sure the parts meet specifications and will arrive on time. An approved submittal authorizes the ordering of a set quantity and quality of material.

Submittals provide a deeper level of detail than is offered in design documents and act as a final quality assurance check before materials and products arrive at the construction site. The dimensions and installation information developed for the submittal also guide contractors during construction. If a contractor installs material that was not approved in a submittal, he is held responsible for replacing that material with the correct item and for bearing the cost of the correction.

Construction Submittal Is Part of a Detailed Planning Process

Submittals follow a defined process that ensures the accountability of all project participants and that construction runs smoothly. Let’s outline the steps.

Step One: Pre-Construction Conference: This step brings together the architect, engineer, and general contractor, and sometimes the owner’s representative and subcontractors as well.

This is also called a pre-submittal meeting or conference or submittals meeting. (The term submittals meeting also describes the meetings that many city and local planning departments offer developers to discuss the outlines of projects that they intend to submit for formal review. That’s a different usage that we won’t go into here.)

In this step, the parties clarify and confirm what the submittal process will be. This includes everything from setting deadlines for delivery and review of submittals to deciding on the format or electronic tool that you will use, and determining how you will route the submittals among the participants.

The purpose of the meeting is to make sure that all the individuals who play a part in the submittal process understand how they will work together and to establish good lines of communication. The participants often discuss how they can avoid submittal delays and mistakes, which increase costs.

Step Two: Submittal Schedule Development: Preparing construction submittals is the responsibility of contractors, but architects and engineers lay the groundwork. As construction plans are being drafted, the design team needs to identify the types of submittals and the relevant technical specifications that are required. You can collect this information in a log or register. To limit professional liability, experts recommend that architects and engineers take no action on submittals that are not specified in the contract drawings.

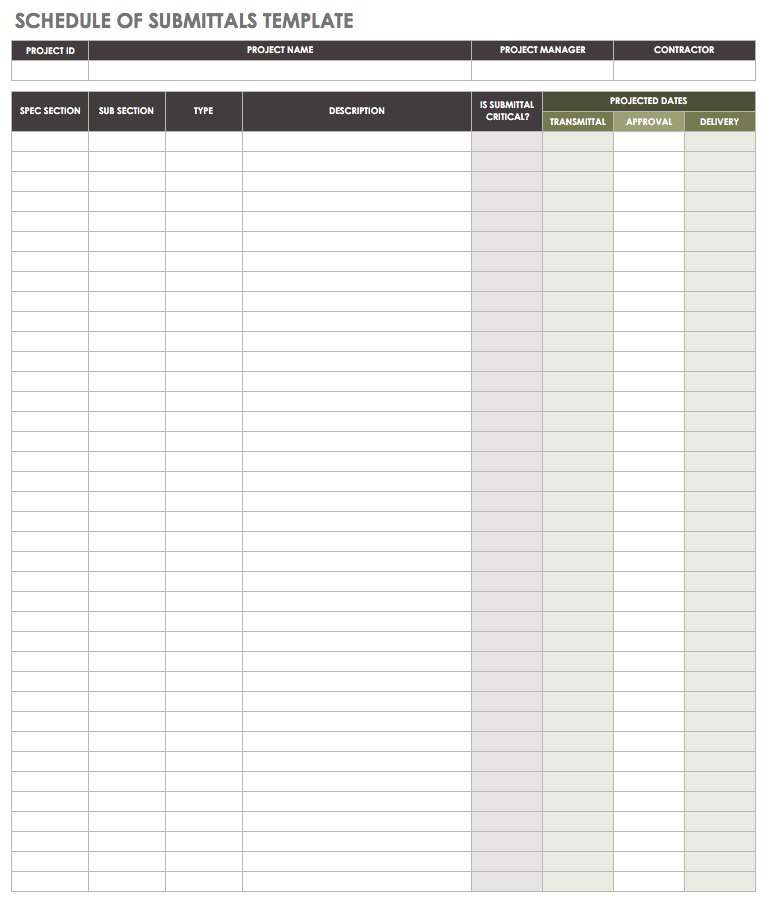

Once the general contractor has the plans, they prepare a schedule of submittals. This lists all the items that need submittals, along with a timeline for the submittals. The schedule of submittals needs to be coordinated with the building schedule, so there is enough time for the architect to review submittals without delaying construction. The submittal schedule should factor in time for the architect to send submittals back if changes are needed. Materials that you need early in construction or that require long lead time get priority.

Download Schedule of Submittals Template

The Engineers Joint Contract Documents Review Committee's C-700 General Conditions, which are best practices for construction documents, call for the contractor to submit the schedule of submittals within 10 days of contract start. The American Institute of Architects (AIA) also has standards covering submittals, and AIA Document G712-1972 is the industry standard for architects to keep track of submittals.

Step Three: Submittal Preparation: The general contractor will either prepare the submittal or delegate it to the relevant subcontractor. The submittal can take many forms, such as shop drawings, physical samples of materials, and data about the items. The preparer should explain any deviation from the construction documents on the submittal.

Download Construction Submittal Template

Microsoft Excel | Microsoft Word | Smartsheet

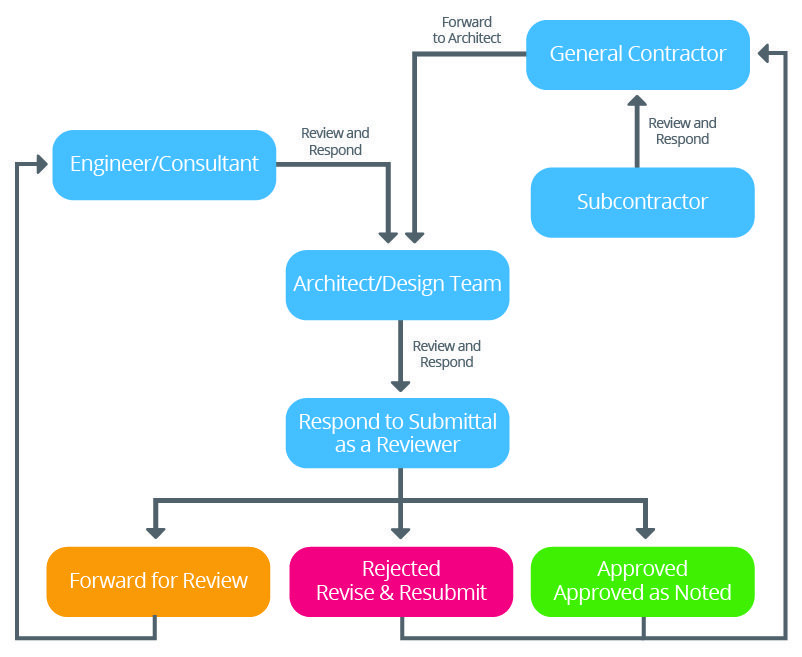

If a subcontractor is preparing the submittal, it first goes to the general contractor for review, who either approves it or returns it to the subcontractor for further work. Once the general contractor deems the submittal acceptable, they stamp it — traditionally, this meant using an actual rubber stamp, but today’s stamps are mostly electronic. The stamp acts as a signature representing acceptance.

The general contractor reviews the submittal to make sure it accurately reflects field conditions, its dimensions are correct, and it meets all contract requirements.

Step Four: Submittal Review: In this step, the architect reviews the submittal. They have a legal responsibility to approve or reject it.

Each submittal must clearly identify the part of the building to which it pertains. The design team is responsible for approving the submittals and making sure the materials selected comply with the requirements laid out in the construction documents and meet the use and performance needs of the design.

The designer or consultant who works on the building system in question reviews the submittal and makes any comments or request changes. It then goes to the supervising architect or engineer. Each reviewer checks the submittal for compliance with the construction documents and the quantity and installation requirements.

Because a shop drawing that is not designated as “rejected” is considered approved, architects and engineers must properly label the outcome of every review. Some common submittal results include reviewed, approved, rejected, revise, or resubmit.

Florida construction lawyer Alexander Barthet says that architects should also qualify their review comments with limiting language, such as: “Review is limited to general conformance with contract documents and design concepts and does not release contractor of its responsibility to determine and control construction means, methods, techniques, sequences, and procedures as well as quantities of materials and dimensions of work.”

During the submittal meeting, an approval workflow is set, and all related documents go to the project’s reviewers in the order indicated by that workflow. Then, the documents go back to the general contractor and subcontractor. Although the process can seem lengthy and laborious, following the sequence ensures that all participants are aware of the status, comments, approvals, and rejections that are occurring at other levels.

No redesign takes place during submittal review. If a reviewer identifies a problem and requires a design change, you should start a new submittal. However, a designer may make minor corrections that do not need to be resubmitted.

The contract will also discuss the length of time allowed for the review of the submittal. This time period can be specific (a set number of days or weeks) or broad (a “timely” review). There is often tension between contractors, who rush to get submittals compiled within a short window and want to start ordering materials as soon as possible, and architects, who often feel squeezed by the contractor to complete their review quickly but want to make sure they have vetted the contractor thoroughly.

The architect stamps the submittal once they have approved it. While this is the architect’s legal responsibility, contractors who do not carefully handle submittals increase the chance of project failure or litigation, says lawyer Robert C. Epstein. So, it’s in the contractor’s best interest to make sure that all materials match the plans and that no unapproved changes have been made.

Types of Construction Submittals and the Information They Include

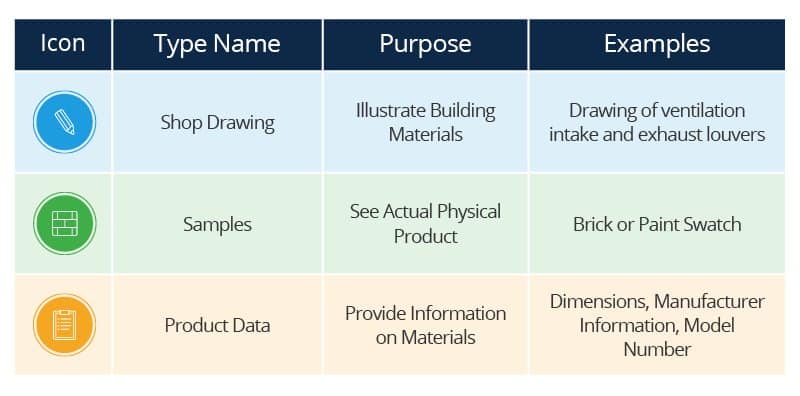

There are many types of submittals, including product data, shop drawings, and samples. As mentioned earlier, the Engineers Joint Contract Documents Committee and the American Institute of Architects have standards governing submittals. The type of information you include will vary according to the type of submittal.

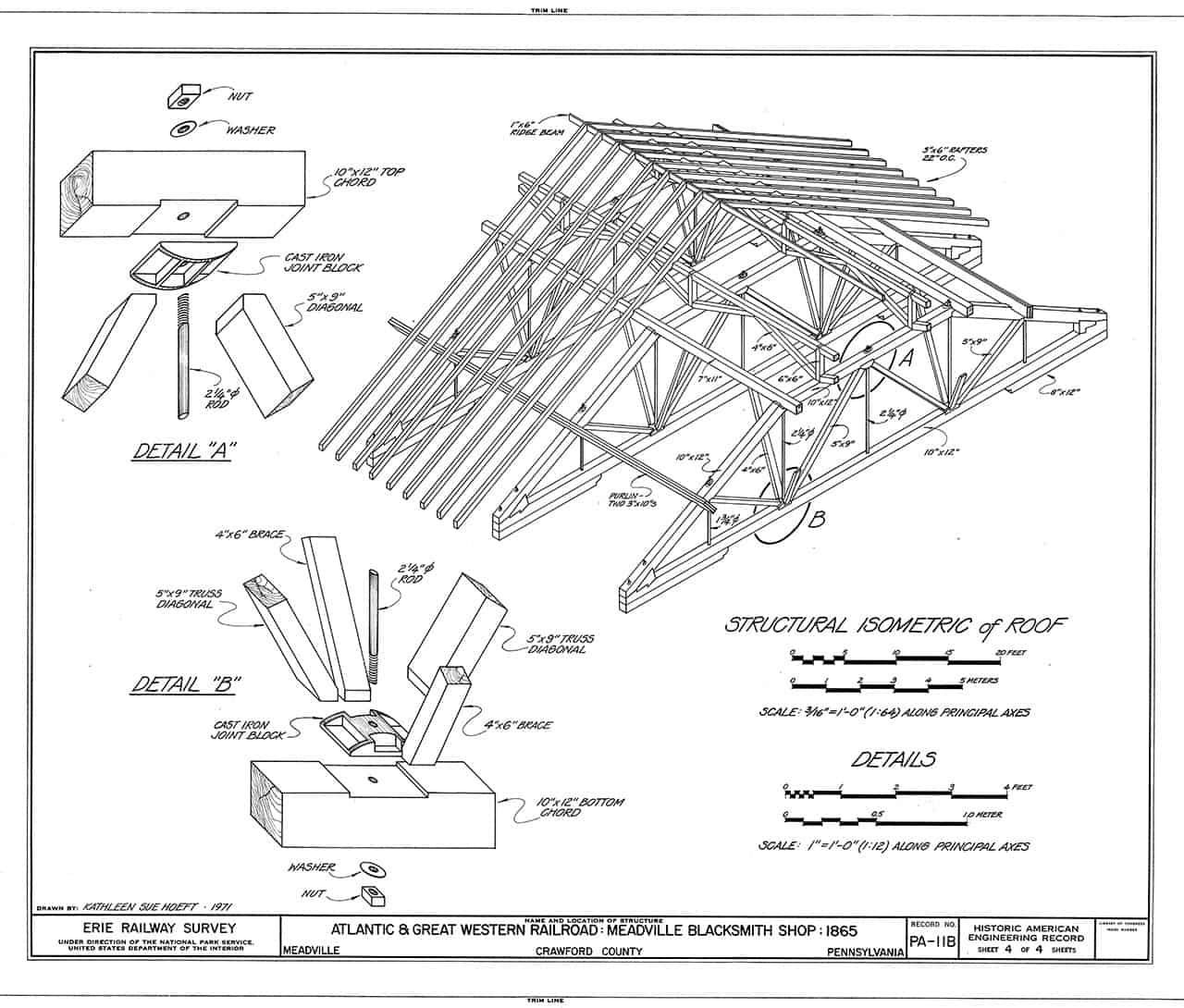

Shop Drawings: These are the most common type of submittal. The American Institute of Architects defines shop drawings as “drawings, diagrams, schedules, and other data specifically prepared for the work by the contractor or a subcontractor, manufacturer, supplier, or distributor to illustrate some portion of the work.”

While the term shop drawing technically encompasses other information beyond images, most construction professionals think of shop drawings as drawings. These detailed drawings are different than the plans produced in the design phase, and true design work should not happen through the submittal process.

These diagrams illustrate how the building components and assemblies come together during construction. But architect and construction expert Ronald P. Bertone notes that shop drawings are not contract documents and that anything contained in a shop drawing does not alter the need to comply with specifications and drawings in the plans. This means that shop drawings are not formally part of the agreement between the owner and contractor and are not legally enforceable. If a contractor wants to do something different than what is in the contract documents, a formal change order must be approved by the architect.

Shop drawings include quantities, dimensions, and performance and design characteristics, as well as other data.

Samples: These are examples of the physical products that builders will use in construction. They can be full specimens, such as a brick, rebar, or quantity of soil, or they can be partial, like a paint swatch or a square of wallpaper. Samples help designers assess aesthetic choices since the texture and color of physical samples can vary greatly from those in catalogs and websites.

Another form of a sample is a mockup, which shows how elements will come together (for example, a wall mockup that includes the window, cladding, and waterproofing). Mockups offer designers the chance to test how well a design concept will work.

Material samples provide information on the material, supplier, composition, and catalog. The AIA says the samples should illustrate workmanship and establish standards for judging the completed construction.

Once the designers approve the submittal, builders store the samples at the construction site and compare them to the material that is delivered to make sure the two match.

Product Data: This provides information about building materials, including dimensions, manufacturer, model, quantity, use and performance characteristics, finish, warranty details, and more. Submittal data may be critical to documenting compliance with standards for origin of materials (such as using American-made steel) or for buying a percentage of project components from women and minority-owned businesses. These standards are generally found on government projects.

Other kinds of construction submissions are also sometimes called submittals but serve a different purpose than illustrating materials. These would include action submittals, informational submittals, submittals at project closeout, submittals on maintenance materials, a quality control assessment plan, an accident prevention plan, schedules, budgets, and more.

Best Practices for Managing Construction Submittals

Contractors need to coordinate the submittal process carefully as part of strategic construction cycle management. Submittals that cover materials needed early in the project must get top priority, but builders also have to factor in lead time for items that need fabrication. This lead time issue may require them to preorder items that are not going to be used until late in the construction process.

These time constraints should appear on the construction project schedule and should indicate dependencies between work and submittals.

If, once construction is under way, a problem arises with certain material, a general contractor may feel the need to vary the item within the approved submittal. However, any change must follow a specific procedure: The contractor would submit the variation in writing to the architect, who would then approve or reject it in writing; the contractor would also update the original submittal to show the revision.

- Incomplete or erroneous specifications of submittals by the architect or engineer in contract documents

- Submittals that were sent to the architect or engineer without first being reviewed by the general contractor

- The architect’s receipt of submittals directly from the general contractor’s subcontractors

- Submittals from the general contractor that are not on the specification list

- A missing or incomplete submittal schedule from the contractor

- Too short of a review time for a submittal due to delays

- Late submittals relative to the schedule

- Shop drawings that contain errors or are incomplete

- Product and material substitutions

- Work installed prior to submittal review and processing

Architects can minimize these problems by following some best practices, Tyde says.

- Write a well-thought-out submittal specification.

- Return all submittals to the general contractor that were not reviewed by the general contractor before being sent on to the architect or engineer.

- Refuse to review any submittals sent directly to the architect or engineer by the subcontractor, and forward them to the general contractor.

- Refuse to review any unspecified submittals, and return them to general contractor.

- Require the general contractor to provide a submittal schedule as part of the contract.

- Write into the specifications how long the architect or engineer has to review the submittal, regardless of whether it is late or not relative to the schedule.

- Return submittals unreviewed when they have obvious errors or are otherwise incomplete.

- Product substitutions need to be comparable, or they are rejected.

- Lastly, if work has already been installed for a missed submittal, then carefully review the installed work for contract compliance. If it is non-compliant, then require the general contractor to revise the work after they follow a proper submittal process.

Risks and Cautions When Working with Construction Submittals

While we mentioned earlier that construction submittals are not considered contract documents, the process does impose legal responsibilities on project members in other ways.

As in the case of the hotel walkway collapse, architects and engineers may be found liable for not upholding their professional standard of care if submittals did not go through proper review or have errors. Contractors can also be held at fault if they do not handle the submittal process properly. Construction experts say that everyone involved in a project should review shop drawings and other submittals, regardless of the contract language, and that the schedule should leave adequate time for full review.

Major construction projects that suffer delays, extensive change orders, or cost overruns often prompt litigation, and submittals can be brought into lawsuits to document performance and communication. But, for a contractor, getting approval of shop drawings or other submittals does not necessarily constitute document contract compliance, and there is legal precedent for courts to deem the approval by an owner’s representative not binding.

Diligence with submittals can minimize the occurrence of change orders, and careful management — especially with the use of electronic tools — can make sure that submittals are accurate, timely, and properly reviewed.

Earlier, we discussed the architect’s professional responsibility in reviewing shop drawings and other submittals. Barthet says that the architect must be familiar with all the contractual requirements of the project and be knowledgeable enough to spot potential construction or design problems in submittals.

Electronic Tools Simplify Construction Submittals

Given the large number of components involved in structures, project participants can find it challenging to keep submittals organized. Traditionally, submittals were pieces of paper, and they were recorded in a log book or register.

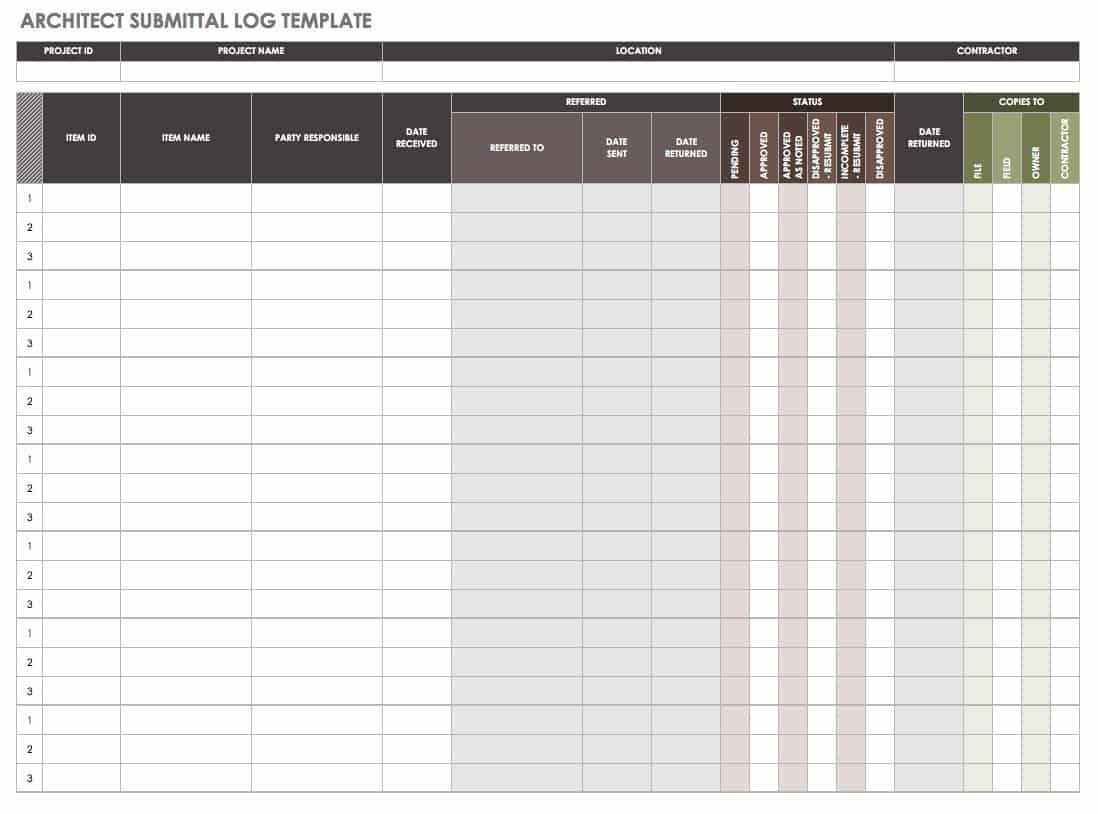

Download Architect Submittal Log Template

Excel

|

WORD

That use of paper and books later evolved into the use of spreadsheets and dedicated software. Today, pros use cloud-based software. These applications have made the submittal process more efficient, and they make managing large document sets much easier. Submittals are easier to find and route to the correct individual. Notes and revisions are well organized and easy to read.

Electronic tools can audit who has reviewed and approved submittals, notify team members when submittals are ready for review or late, and attach the submittal to the relevant part of the project plan.

“Electronic submittals speed up the process and have shortened the review cycle. The process is now updated instantaneously when a submittal has been reviewed,” Spiegel says.

The digitization goes beyond document management, he says. Fabricators are using bar codes on components, so they can be easily tracked and matched to plans. The trend toward building information modeling (BIM) makes it possible to link materials to electronic drawings, making drawings more detailed and accurate.

Common Submittal Pitfalls (and How to Avoid Them)

Construction experts say that submittals are prone to some common pitfalls. With diligence, however, you can avoid or minimize many of them. Still, both contractors and architects say their training does not adequately prepare them for dealing with submittals, and they learn on the job. Some of the problems reflect the different agendas of contractors and architects when dealing with submittals. Let’s review some of them.

- Friction over Timeline: Contractors often find submittals tedious and time consuming, and when they finally finish them, they want quick approval from architects. Architects, on the other hand, sometimes complain that they receive submittals later than they should and then immediately face pressure from contractors to approve them. Architects and engineers also say that general contractors occasionally do not give subcontractor submittals enough scrutiny and instead rely on the design team to catch any errors. Spiegel says that compressed timelines on more projects add to these pressures, but he urges an emphasis on teamwork, starting with the preconstruction conference to avoid adversarial relationships.

- Not Sticking to the Process: Contractors can perceive architects as misusing the submittal process to insert design changes, such as switching colors. Architects feel that contractors sometimes do not put enough effort into understanding their design intent and cut corners by relying on the architect’s own drawings rather than on more detailed shop drawings in the submittal.

- Lack of Performance Indicators: Both sides understand that mismanagement of submittals can lead to mistakes, excess costs, and delays, but improvement has been limited by a failure to track performance. In the Journal of Advanced Management Science, Abdulrahman Alsinaidi of the Salman bin Abdulaziz University in Riyadh, Saudi Arabia calls for construction managers to use a performance index to show how each party is performing in the submittal process.

Recommended Resources for Further Reading about Construction Submittals

- Brown, James C. and Cavaluzzi, Gerard P. "Shop Drawings and Other Construction Submittals: Legal and Engineering Perspectives." Eau Claire, WI: Lorman Education Services, 2014. Pp. 11-12, 42.

- Evans, Mark, Bricker & Eckler LLP. "Submittals: Things You Always Wanted to Know, but Were Afraid to Ask."

- Anumba, C.J., Baldwin, A.N., Bouchlaghem, D., Cutting-Decelle, A.F., Dufau, J., Mommessin, M., and Prasad, B. "Integrating Concurrent Engineering Concepts in a Steelwork Construction Project." Lancaster, PA: Technomic Publishing Co. Inc., Concurrent Engineering, 2000. Pp. 199–210.

- Anumba, C.J., Cutting-Decelle, A.F., Baldwin, A.N., Dufau, J., Mommessin, M., Bouchlaghem, N.M. "Integration of Product and Process Models as a Keystone of Concurrent Engineering in Construction: The ProMICE Project." Proceedings of 2nd European Conference on Product and Process Modelling, 1998.

- Dubois, A.M., Flynn, J., Verhorf, M.H.G., Augenbroe, F. “Conceptual Modelling Approaches in the COMBINE Project.” Dublin: Final Combine Workshop Paper, 1995.

Improve Construction Submittals with Smartsheet

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.