What Is an Integrated Product Team, and What Is Integrated Product Development?

Integrated Product Teams

An integrated product team consists of members who represent every discipline involved in the creation of a specific product or program. These teams involve stakeholders like users, managers, developers, engineers, and designers. Such teams are appropriate for complex, long-term projects that require constant collaboration, deep understanding from non-practitioners of a particular field, and frequent review. According to the Department of Defense (DoD) practices, they come in at three levels:

- Overarching IPTs which handle strategy, report on the program, and resolve issues.

- Working IPTs which find and solve issues in the program and provide status updates to stakeholders.

- Program IPTs which execute the plan and are closer to the actual work.

Example: Government Contractors

A common area that uses integrated product teams is in defense contracting with the U.S. government. Suppose that the air force is developing a new type of airborne drone. Though the expectations of the project are great, the budget is less than it was for previous projects, which means tighter deadlines to limit contractor fees, and potentially procuring from a number of smaller vendors rather than an overhead-heavy mega-producer like Boeing. To make several small shops with lower price points feel like a powerhouse, they need to work together as an integrated product team.

In this example, the air force already has plans and benchmarks under its roof, but needs parts and technological innovation to make the drone faster with enhanced targeting accuracy. The targeting system developers, the parts suppliers, the schematic designers, and propulsion engineers all need representatives in one team to ensure they meet deadlines with minimum rework requirements. Careful planning directed by the IPT will also prevent costly bottlenecks where one team is waiting on another before they can start their work.

Such a team will also include members responsible for budgetary oversight, who may grant the funding in stages to keep the project on track. They’re essential to keep in the loop - after all, it is taxpayer money. On-budget and on-time development for government agencies relies on a solid team working as one, and in the case of the DoD, it can be a lifesaver.

Example: Corporate Brand Extension

Let’s say a major consumer brand, such as Apple, wants to create a brand extension. They’ve already mastered home computers, smartphones, tablets, and watches, and now they are breaking into automotive with the oft-rumored Apple Car. Apple is no stranger to procurement and vendors, but this is a whole new arena of engineering and design challenges. Without the tight integration of software and hardware they’re known for, the Apple Car might be a flop.

In this example, Apple would devote head designers responsible for form-factor and UI in their smaller products to this project, along with brand managers. Engineering and development would be key roles in the integrated product team too.

At the same time, Apple knows little about automotive and doesn’t own any factories capable of manufacturing cars. The company would need to partner with vendors for these duties, and recruit design and engineering leadership who are experienced in this field into the integrated product team as well. Then they must take into account parts procurement, safety testing, and other factors unique to this space.

To get a car that’s on-brand, highly functional, and integrates with their other devices, Apple needs key players all working together and understanding the parts of the project for which they aren’t directly responsible.

Principles of Integrated Product Development

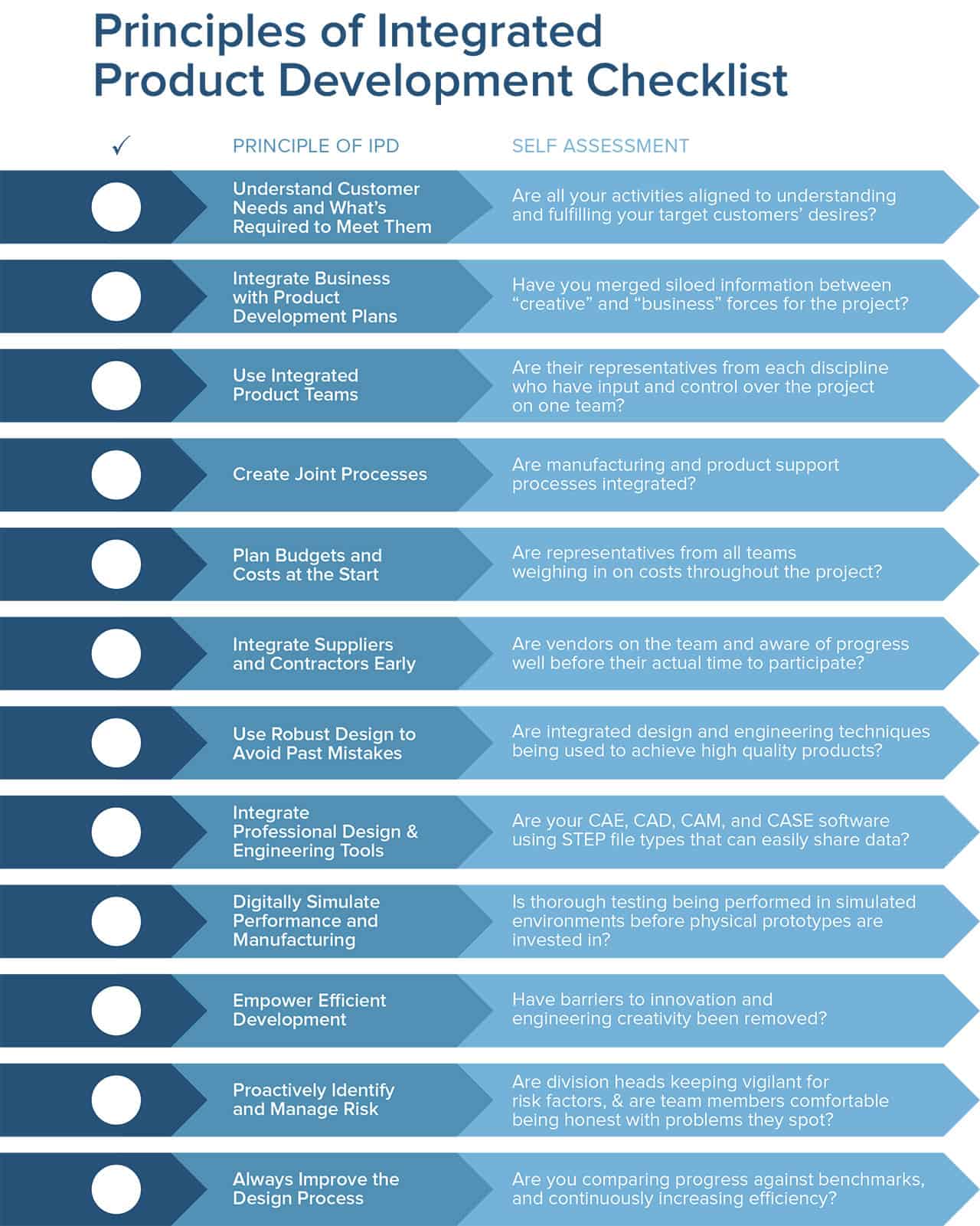

Integrated product development is simply the practice of building and effectively using integrated product teams for a long-term, complex, new product development. Though it’s easy to define, IPD has 12 major principles that you must understand in order to put it into practice:

-

Understand Customer Needs and What’s Required to Meet Them

Products answer a customer’s needs and wants - until these are met, nothing else matters. Once you define these, strive to track the project against them to reach a minimum viable product (MVP). This way, you can avoid scope creep that pushes out your delivery date. -

Integrate Business with Product Development Plans

It’s important to keep non-creative forces involved in the process and team because investments in R&D on one particular project might become more justifiable if they can serve the stakeholder’s needs continuously in the future. Having a long view on where development stands in the overall strategy, branding, and investment is important to completing a project. -

Use Integrated Product Teams

Obvious as it might seem, it’s important to bring in stakeholders from every relevant discipline to make new product development a success. These areas could include marketing, manufacturing, quality assurance, design, and more. Most importantly, they must be empowered for self-direction to achieve the best possible results. -

Create Joint Processes

The way you design your manufacturing process and product support process should be joined with the product’s design to optimize how well it works both technologically as a device and competitively in the marketplace. -

Plan Budgets and Costs at the Start

With an integrated team in place, you can get realistic feedback on strategies and proposals right away. Only a developer will know how feasible a budget is in creating software, just as only a plant manager may know how far over a planned schedule production will go. Discussing budget early and incrementally also reduces risk. -

Integrate Suppliers and Contractors Early

Unlike processes that favor just-in-time fulfillment, integrated product development demands bringing in even fully-remote external team members as soon as possible. This means you should favor long-term relationships with suppliers, with whom stable schedules can be built and met with fewer stopgaps and at a lower cost. -

Use Robust Design to Avoid Past Mistakes

Put different engineering techniques into place to ensure high quality and reliability, allowing for robust designs without the risk of failure. Always learn from past mistakes, and perform regular reviews where you formally address and ultimately solve all issues and mistakes. -

Integrate Professional Design & Engineering Tools

Combine design tools like CAE and CAD software with process tools like CAM software and development tools like CASE software, to allow for efficiency of data storage and sharing. All parts of the team responsible for creation should understand the whole process, which helps minimize rework. -

Digitally Simulate Performance and Manufacturing

Mockups should be a major part of your process, securing proof-of-concept for complex systems like circuits, wireless interference, and more. By integrating them early in the process, iterative building and testing isn’t required before creating a prototype. -

Empower Efficient Development

Though all stakeholders should have a voice on the team, product development is about creation, which means minimizing red tape. You must place your trust in designers, engineers, and developers once they have their marching orders, and design review processes accordingly. -

Proactively Identify and Manage Risk

Minimizing risk is a major feature of IPD, and as such, division heads must actively seek out project-derailing problems at all times. Creating an open environment where contributors aren’t afraid to be honest about potential risks they spot is a big help in that regard. -

Always Improve the Design Process

Just as you must be vigilant for risks, so too must you be for inefficiencies. Improving the process is a process in and of itself - compare progress against benchmarks, see where rework happens frequently, integrate more of your tools for automated handoff, and invest in team training of IPD techniques.

Download Principles of Integrated Product Development Checklist

Advantages of Integrated Product Development

On the surface, a bunch of different experts working together sounds like a pretty obvious plan, but the advantages they yield for new product development go far beyond individual skills. What makes IPD so beneficial is that it:

Enforces Modernization and Technology

Because IPD thrives on efficiency, it demands that new “shortcuts” and automation be adopted quickly. If CAM and CAD software can automatically share data, why shouldn’t you use the feature set? If flexible project management software can automatically notify everyone of the status of the project and their specific new priorities, it should be done. Outside the managing of the project, innovations in development and manufacturing are made to beat competitors to market. Making long-play investments in R&D for your current project may pay off in the future because the IPT you’ve formed will be working together even more efficiently.

Minimizes Costs

IPD’s principle of continuous process improvement, MVP, and reducing redundancy and rework means costs decrease. Modeling your products digitally limits the number of prototype iterations you have to produce. Long-term vendor relationships mean bulk orders and familiarity working with one another, which reduces miscommunication and costly project chokepoints. You can find savings in every corner of a project.

Reduces Risk of Product Failure

Enforcing, regular, and thorough communication means no design flaw or manufacturing error will slip through the cracks. Involving all stakeholders early means future issues become present, known factors, allowing you to account for everything. As long as the team is working together and sharing notes, product failure is an unlikely outcome.

Favors Quality and Innovation

Just as product failure is reduced, so too is quality favored by the process, for the same reasons. The strongest minds of each discipline come together and collaborate, rather than non-practitioners dictating direction or partially-committed vendors just phoning in a one-time job. With all teams engaged and invested in the outcome, the best ideas and work will naturally emerge.

Democratizes Development

On the note of ideas, IPD’s true advantage is that it encourages participation from all stakeholder organizations. With so many perspectives, from the different disciplines on the teams to the customer perspectives brought from research, thoughtful consensus is the only way forward.

How to Form an Integrated Product Team

Creating an IPT takes more than the individuals involved - it requires a well thought-out framework. Providing sections of this is Darren Saravis, CEO and Founder of Nectar Product Development, a firm based entirely on the IPT model. Some background about Nectar Product Development from Darren:

Use the following framework to start organizing your integrated product team:

Develop the Plan

Begin with a customer focus, determining the needs of your customers, which products meet those needs, and what are your current capabilities. Perform a gap analysis on these factors, finding the niches that aren’t being properly served - though you’re building a team; the team must cater to the product in IPD, not the other way around. Then, set up your team structure and determine required resources like hardware, software, space, and outside contractors.

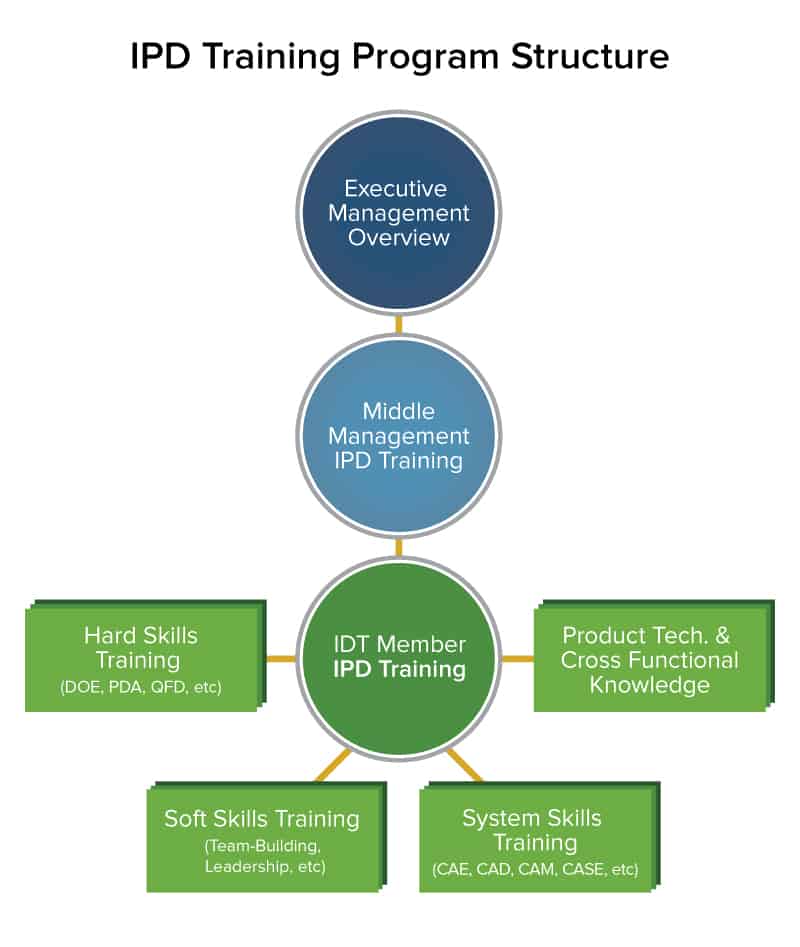

Training and Communication

Once you gather all the elements, it's time to train the team. Communicate the principles of IPD, and structure incentive programs to reward following the plan. Establish team leadership who can keep individual team members on the IPD philosophy. Don’t skimp on investment in training, and use it as an opportunity to cross-pollinate teams who previously seldom interacted, like business strategy and software developers for example. Give them a common language to share.

Improving Development Processes

Saravis explains, “Successful product development starts with a tested, well-defined and well-executed process. The plan must then be followed by a logical and disciplined sequence of development phases. Nectar Product Development has perfected the end-to-end process and what each phase entails. This enables a development team to turn great ideas into highly successful products.”

Define Team Relationships and Responsibilities

Saravis shares how they set up team relationships at Nectar, “Nectar unites design and engineering teams to create a harmonious work relationship that translates to intuitive products. In the process we call N-Connected, designers and engineers collaborate to support each other’s phases. This cultivates teams to create innovative and intuitive products. This unique cross-functional process creates a harmonized workflow.”

Define Metrics

Determine what is success, and give similar metrics to different teams for meaningful comparison. Obviously, you don’t expect engineers to handle marketing and vice versa, but timely delivery, responsiveness, and the amount of rework required are good common measures.

Record Processes, Activities, and Decisions

IPTs must continuously improve, so keep a record of everything. Divvy the task up to departmental leaders, and gather everything in a single repository. When you weigh the outcomes, it becomes clear what decisions and processes led there.

Why Integrated Product Development Fails to Take Hold

If it is truly advantageous to use IPD principles and form integrated product teams, why do some organizations never do so, or try to yet fail? There are numerous reasons that, even with the best intentions, management and employees can’t launch an integrated product team. Here are some pitfalls to avoid:

Self Overestimation

Though the concepts are not difficult to understand, putting them into place takes mastery of project management and coordination at all organizations involved in IPD. If management reads up on the IPD concept and shuffles the org chart without embracing the spirit of the methodology, it will never gain a foothold. An experienced perspective or even a team of consultants might be necessary to help get things set up and train everyone.

Low Prioritization

Setting priorities is an efficiency long-play; results will not happen overnight and there are too many cogs to get the machine working right away. If stakeholders see it as a ‘fad’ project management style and disengage the second that results don’t materialize, it cannot succeed. Commitment is required.

Cultural Inertia

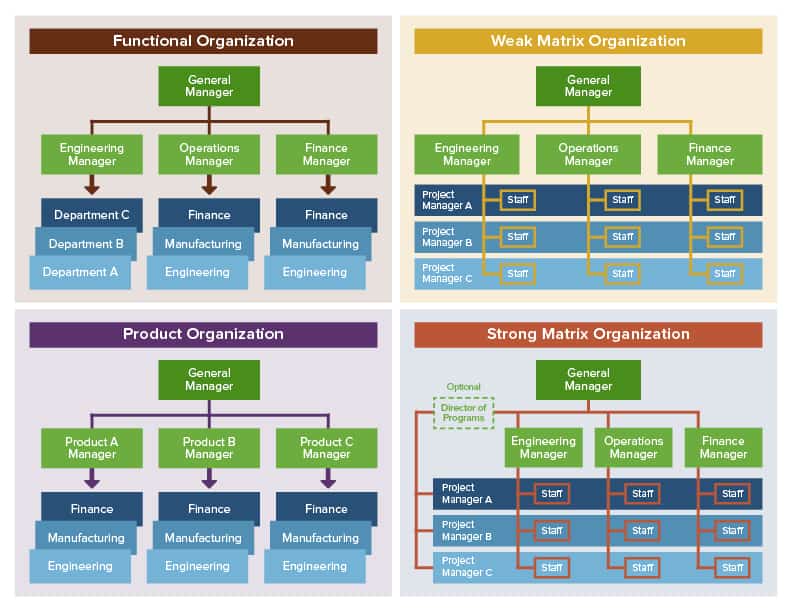

Not every company’s culture is set up to hit the ground running with IPD principles. A developer studio will understand Scrum, and a product design agency may understand multi-org coordination. But a corporation with a top-down command chain may fail to divest enough autonomy to product-level stakeholders, or involve the employees who implement the changes. If an organization is resistant to change, it might not be able to handle IPD. The following chart shows how to evolve from a weak hierarchy to a strong IPD structure:

Unclear Roles

When you form a team, but there is no real guidance on who is responsible for what, and who reports to whom, the project may be unmanageable.

Lack of Follow Up

After implementing a team, an important part of the process is follow-up and reporting. If management isn’t checking to see that the process is being implemented and observed, the team members might lose their motivation to follow it before self-serving benefits are rendered (like less rework for their portion of the project).

Lack of Investment

If there isn’t enough time or money to train all the IPD practitioners, and you don’t invest in improving the process over time, IPD may fail. Again, it is a long-term investment with rapidly increasing returns, but only when you tend to it. You gain efficiencies not only in smoothing out errors at each iteration, but also improving working relationships among all team members.

No Coordination

It isn’t enough for management to follow through and commit - the team members must accept their sometimes time-consuming new responsibilities. IPD places more power and higher-level coordination in the hands of “low” level employees, like the product designers themselves, for example. Communicating with vendors might previously have been the purview of account managers, and working out scheduling may have been the realm of project managers, but now designers have to do a little of everything. If team members reject or neglect their new roles, the project will fall apart.

Disincentives to Participate

Just as a company’s culture might not be set up for management to enable IPD, a company’s systems might not be set up to incentivize team members to participate in it. For example, if bonuses currently in place reward cranking out high volumes of work, a team member might not put in the proper collaboration with members from different disciplines which may delay their delivery. When setting up IPD, be sure to review and realign policies and incentives structures.

Key Factors to Make IPD Adoption Successful

You’ve seen why IPD benefits organizations, how to form a good team, and why trying to implement it can be hard. So how do you increase your chances of success? The best teams have the following in their favor:

Aligned to One Objective

Product development has one goal - addressing customer requirements and appealing to them. It’s important to align all activities and all parties toward this goal, so motives are clear and team members know what ideas are worth fighting for.

Scientific Review of Plans

Data collection is key to bolster decision making for the continuous process and strategy improvements IPD demands. How long did this task take? How many tests did you run? Why were development and design out of sync on needs for a part of it? With better understanding, the whole team can improve.

Investing in Human Capital

Give teams resources to experiment and improve, and achieve the goals set forth for them. Hire the extra pair of hands, get the time-saving piece of equipment. Set up the team for success, and let them know that the broad view of IPD is what enables it.

Empowered Team Members

You must empower team members carrying out tasks to make decisions. The troops know the situation on the ground better than commanders back at the base, and if they know that success is in their hands, they’ll make the best choices possible.

Open, Factual Discourse

When discussing alternate viewpoints and plans, ensure that it never shifts from discourse to argument. Keep attention on the facts, not feelings, in the effort to build the best product possible. Further, don’t let seniority rule above facts - if a junior engineer is expressing a technical impossibility to a senior program manager and has test data to back her up, defer to this data.

Support for Consensus

Again, no overruling or flexing power. When concluding discussions and reaching a consensus on decisions, everyone up and down the team’s ranks must respect them. The organization must own it. For team members to believe in the process, they must see that even those above them respect the final say.

Respect for Minority Opinions

While consensus is important, team members should still respect opinions that did not achieve it. Camaraderie is essential for moving forward on the project without resentment or bitterness.

Clear Responsibilities

When developing the plan, define the roles of each team member in a concrete way. If someone wants to step up and help more, that’s fine, but they must first understand their individual role and ensure their work is complete so there isn’t a gap in coverage.

Frequent Meetings

Meetings are not everyone’s favorite part of the day, but they are essential to success of IPD. Encourage adoption by structuring them all with an identical outline, such as Scrum, and make sure they end quickly. Hold these at least monthly for the wider team, and weekly for the segmented teams.

Project Management Tools and Integrated Product Development

A key part of integrated product development that is touched on but never explored in much documentation is project management (PM). Most individual teams have their own project management solutions, be it methodology alone, or the tools that enable them. The humble to-do list. The sticky note Kanban on a white-board. Or even a full-featured software that everyone uses. However, the trouble with many PM solutions is that they’re geared toward one particular kind of workflow, which is not enforceable throughout an integrated product team made up of entirely different disciplines and working styles. Though they may all keep their own software within their team, the cross-functional team must have a unified system that fits everyone’s combined style.

What features are ideal for an integrated product team’s project management software?

Team Agnostic: The best project management tool is flexible. It may have several proven ways of functioning, but it also has countless other ways to work that users can calibrate perfectly for your integrated product team. It should allow your team’s stakeholders to view project data as in-depth as they need, in visualizations that are easy for them to navigate.

Has All the PM Staples: Can it provide a drag-and-drop Kanban workflow for the Agile sprinters? Can it create Gantt and Waterfall charts with a traceable critical path? Is it editable like a spreadsheet for those who are focused on the budget? Can it present a simple list of tasks and subtasks? Each discipline or level of team member might be most comfortable viewing their data and tasks in a different manner, and it should cater to all of them.

Highly Scalable

Although downloadable software is getting rarer these days, there are still some enterprise-level companies who choose it for security reasons. When it comes to a multi-organization project management tool, go for the cloud and choose a SaaS model. Most have options for encryption that meets all reasonable standards, and they’re just much easier to work with for all involved. You can add and remove users on the fly, and adjust permissions easily, which is perfect for clients and contractors.

Customizable Dashboards

For the project managers, there’s all the data; for the executives, there’s the stripped-down report. Your PM tool should enable simple reports and dashboards with just the data that top management needs to determine whether things are on track, and where to allocate budget or training.

Automated

Process efficiency is a feature of IPD, which means the tools you use to manage it should be able to get better with time. Many of the stakeholders who function as project managers in an integrated product team are also responsible for other vital tasks. Create more time for stakeholders by enabling automated notifications, assignments, and more.

With a robust project management system in place, your integrated product team can get a transparent look at where day-to-day operations are along with the big-picture of overall progress. A strong process, the discipline to follow it, and a tool that makes it all easy will get you from concept to production in no time.

Resources for Integrated Product Teams and Integrated Product Development

Graduate programs catering to this “new” school of integrated product development have sprung up at universities across the globe, and help participants gain a type of experience not typically possible before joining a team performing this sort of work. Often, these innovative programs will pair students from entirely different degrees together for shared long-term projects, simulating the cross-departmental collaboration required to succeed in the world’s largest integrated product development firms. Some notable examples in the U.S. follow:

Strategy & Innovation Department

Boston, MA

Management of Innovation & Product Development MBA

Pittsburgh, PA

Georgia Tech College of Management

Technological Innovation: Generating Economic Results (TI:GER) program

Atlanta, GA

MBA Entrepreneurship & Innovation Track

Cambridge, MA

University of California Irvine

MBA Innovation & Entrepreneurship

Irvine, CA

Glossary of Integrated Product Development Terms

When working on integrated product development or becoming a member of an integrated product team there are a few key terms worth knowing. Here’s a brief overview of some of the most popular.

Benchmarking: Setting a standard of quality or progress that must be reached, for later comparison with the actual status of a project to determine success.

Computer-Aided Design (CAD): Software tools for visualizing and creating designs and mockups in 2D and 3D virtual spaces. The tool helps create work faster that’s of a higher quality, and enables communication and automation of lower-level tasks. Blueprints, schematics, parts identifiers, and fully-realized 3D models are common output.

Computer-Aided Engineering (CAE): This software provides important tools for hands-on members of an integrated product team. CAE apps take the models of CAD and go further by applying physical properties and prototyping to the parts. These might include fluid dynamics (like for fuel), stress analysis (breaking point and malleability in manufacturing and in consumers’ use), heat, circuitry, and more.

Computer-Aided Manufacturing (CAM): Software that controls the physical tools that bring designs and prototypes to life. It guides machines to carve out the working parts to exacting specifications. The software has special considerations for physical wear as a result of creating the parts that help the machinists operating them.

Computer-Aided Software Engineering (CASE): Tools that help developers and engineers build and maintain high-quality software. They might use CASE to combine several different parts of software: business, the development itself, data validation, metrics and analysis, and project management.

Design of Experiments (DOE): This is a method of projecting the relationships between factors that influence a process and the output of that process. The scientific method is an example, taking into account biases and unintended hints that might influence an experiment’s results.

Electronic Design Interchange Format (EDIF): A “vendor-neutral” format for storing electronic schematics. EDIF enables different software to exchange accurate, lossless data, which aids in integrated product development.

Finite Element Analysis (FEA): A method of digitally simulating and analyzing how engineering structures act and react under various conditions. The process works by dividing an engineering project like IPD into its constituent components to make reasonable assumptions about their joined behavior, hence the “finite” part of the name.

FMECA: This stands for Failure Mode, Effects, and Criticality Analysis and is a method of analysis that records the likelihood of failure of an engineered product and how serious the consequences of that failure would be. It can be done on parts, or at the build level.

IDEF: Integrated Definition is a group of engineering modeling languages that help with simulation, design, analysis, and more.

Product Development Assessment (PDA): This methodology helps teams benchmark your IPD process against an extensive list of industry-standard best practices.

Quality Function Deployment (QFD): This process helps an IPT maintain focus on the customers by identifying and resolving issues related to wants and needs, and enforcing extensive market research.

STEP: “Standard for the Exchange of Product model data” or “STEP” is the international standard file type for product model data, which involves CAE, CAD, and CAM data exchanges. With this standard in place, IPD becomes possible because there’s a common language spoken among the software that all teams use.

Work Breakdown Structure (WBS): This is a project management framework that breaks a larger project into smaller pieces, especially for the purposes of estimating and tracking costs. You can learn more about WBS by reading Getting Started with Work Breakdown Structures or create your own with a WBS template.

Empower Integrated Product Teams with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.