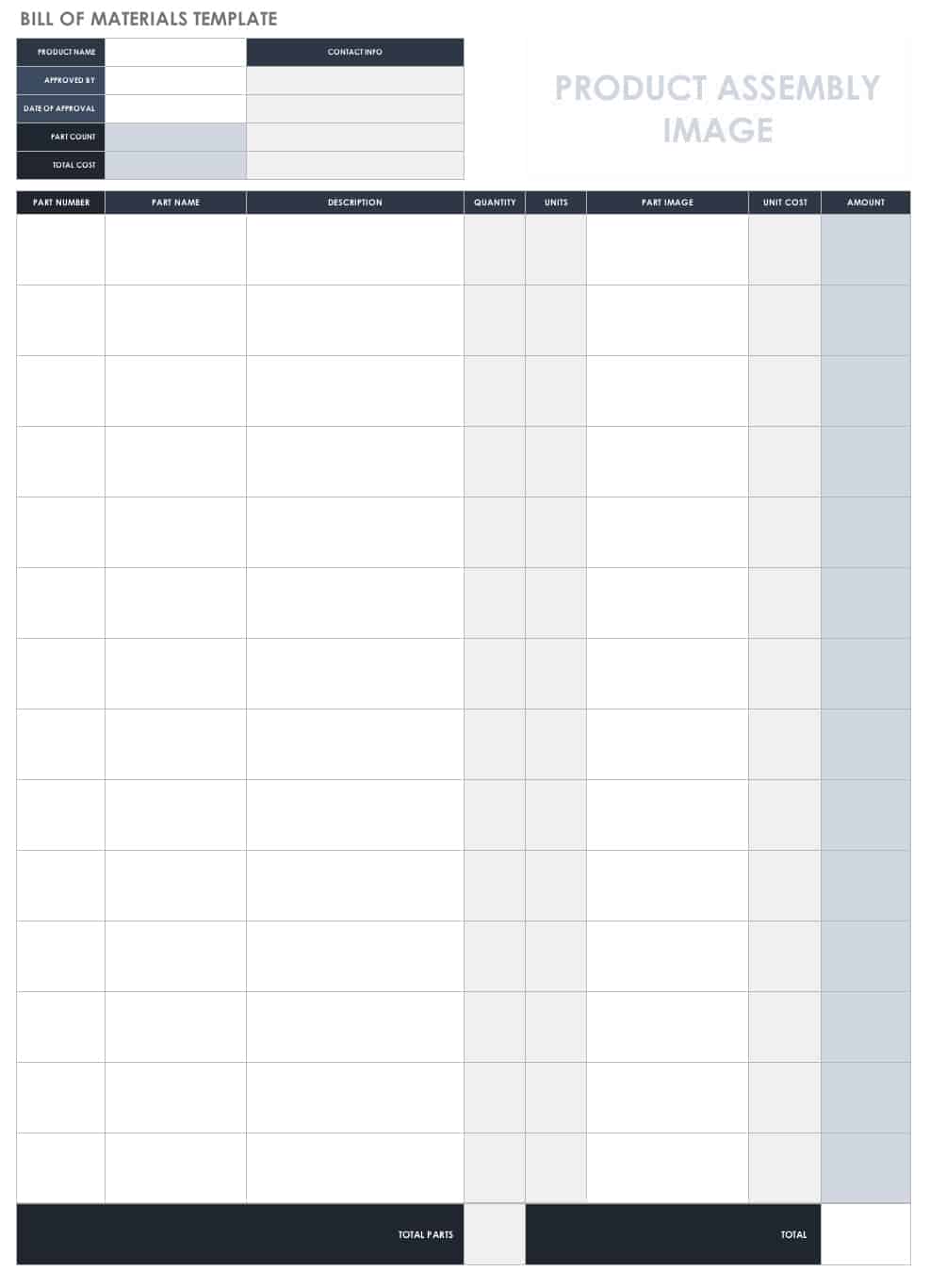

Bill of Materials Template

Use this template to create a simple “spare parts” list in Microsoft Word. The chart offers space to include part number and name, description, quantity, units, and unit and total cost, as well as approval signatures and dates, so you can proceed through production.

Download Bill of Materials Template

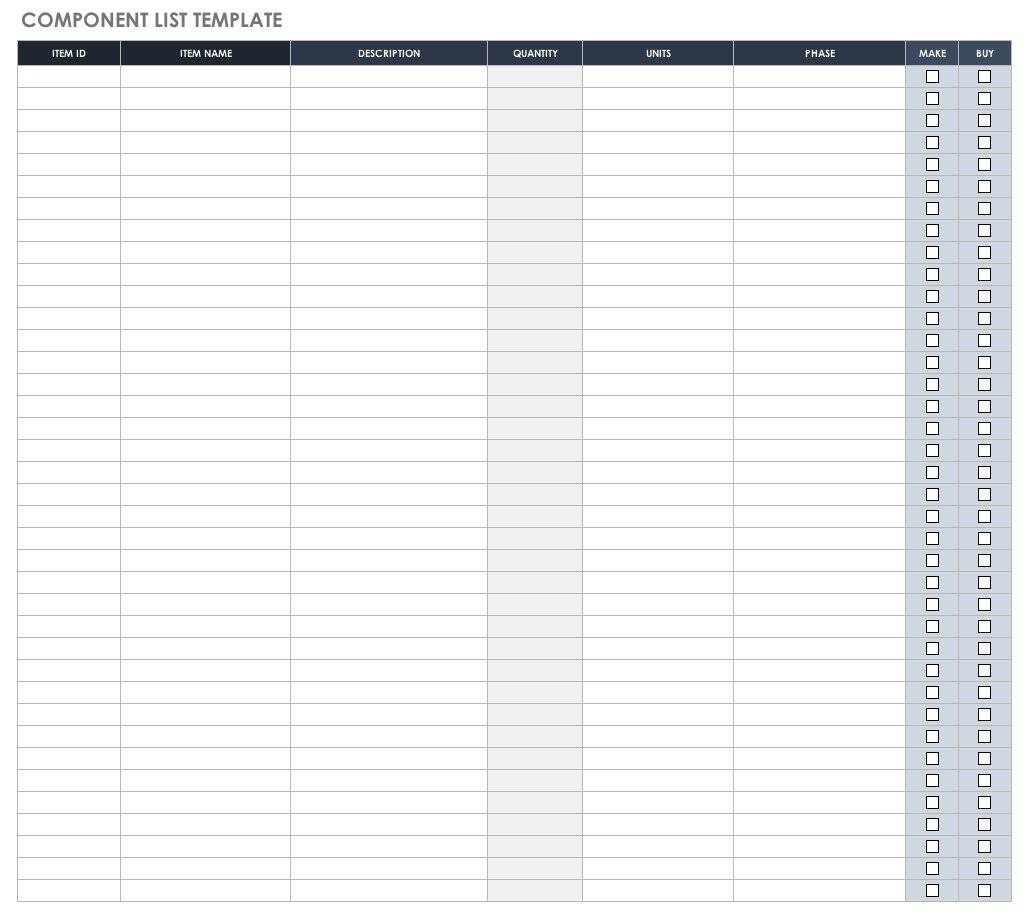

Component List — Excel

This is a simple list of every component needed to complete your product, housed in an Excel spreadsheet. List the item name and number, description, quantity, and units. The template also includes space for notes about which phase of production each part will be used in, and whether you will make or buy each component.

Download Component List Template — Excel

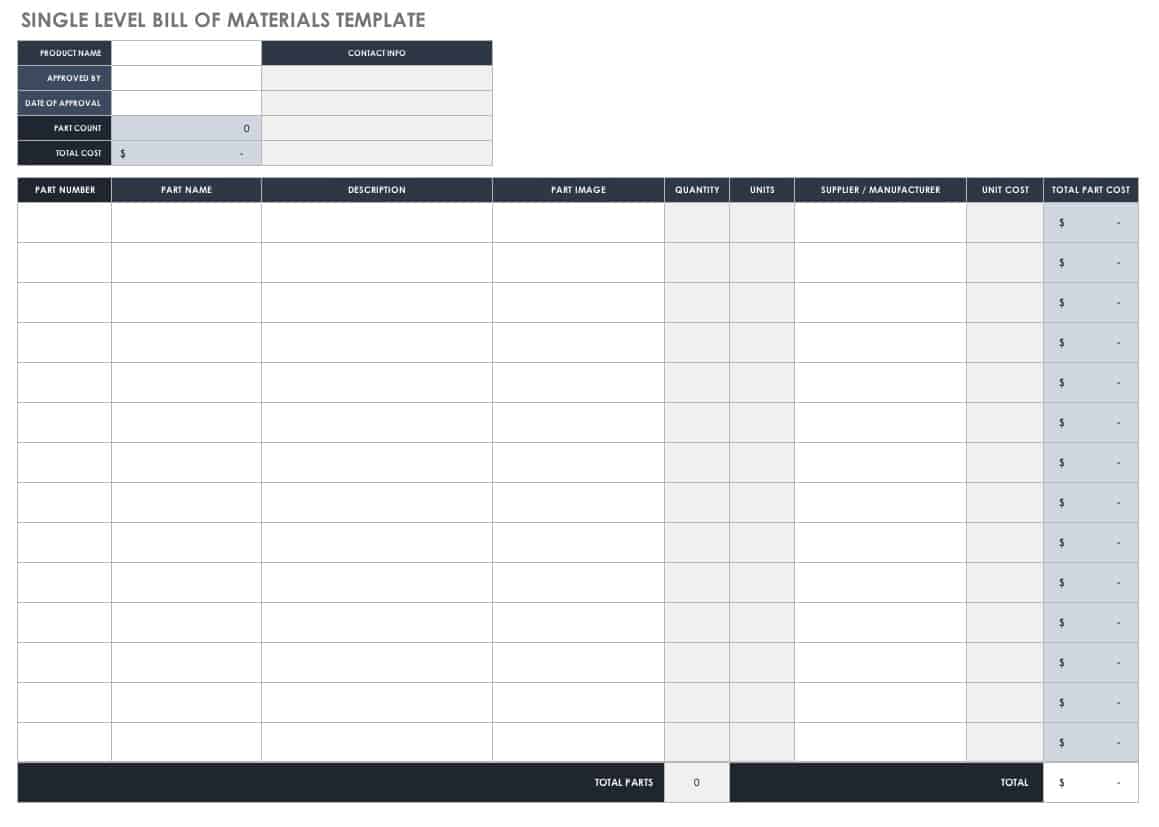

Single-Level BOM Template — Excel

This is a single-level modular model. List the part name and number, description, quantity, and units, along with information about the supplier and a picture of each product. This is a good option if you are building a relatively simple product without many relationships among components.

Download Single-Level BOM Template — Excel

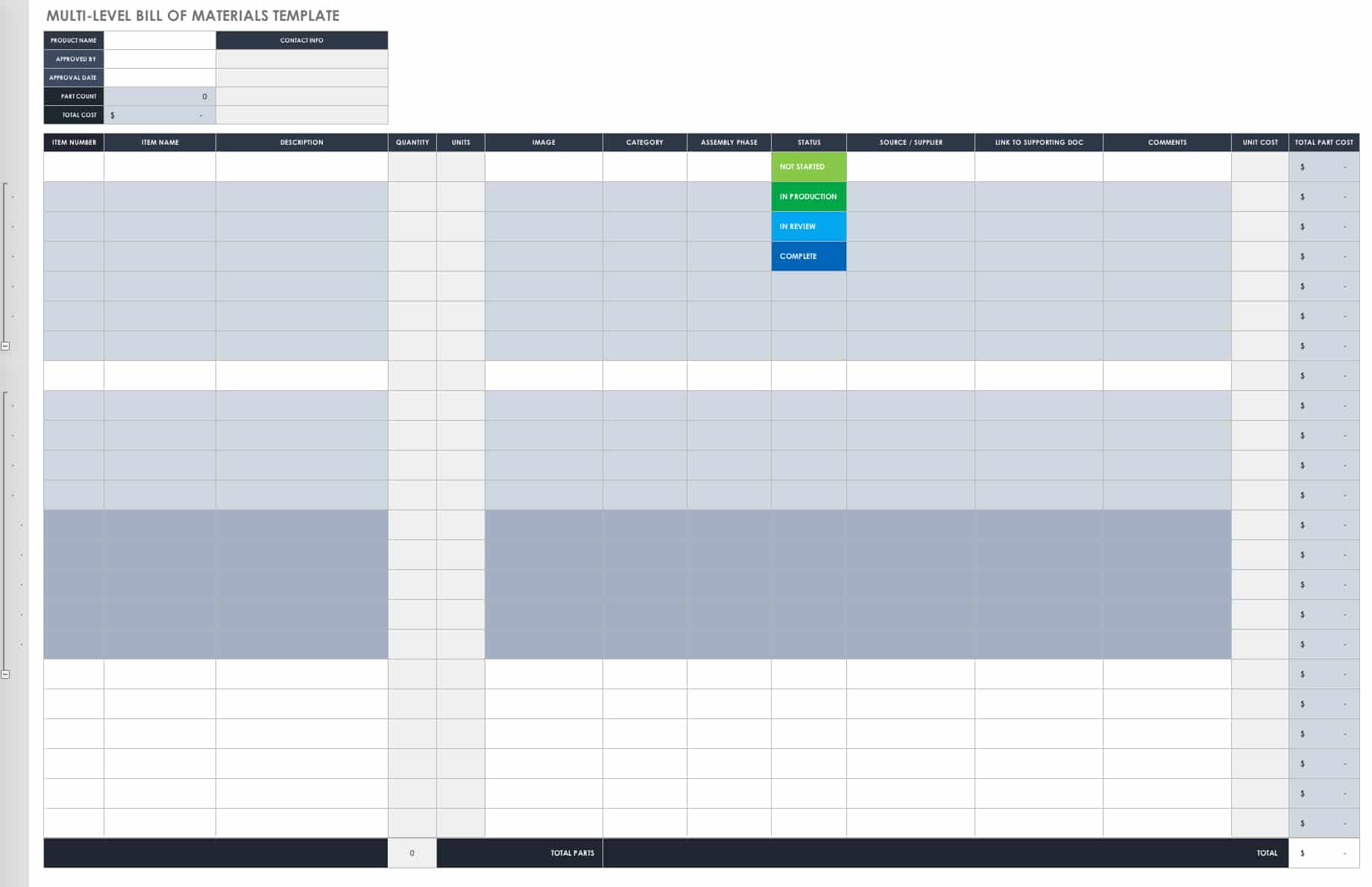

Multi-Level BOM Template

This modular template includes multiple levels of hierarchy so that you can visually see the relationships among parts and components, but you can adjust the template to add as many levels as needed. There is also space to include information about assembly phase, production status of each component, and supplier contact information. If you need to create a bill of materials for an engineering or manufacturing context, you can include information from either the design or manufacturing perspective, and add or edit columns for more information.

Download Multi-Level BOM Template — Excel

Supplier List

If you are contracting with multiple vendors or suppliers for a project, this template will help you gather contact information and stay organized. List all contact details, the items supplied, order date, and any other comments so that you can ensure you receive all materials on time and up to standard.

Download Supplier List Template — Excel

What Is a Bill of Materials?

A bill of materials is a list of all the materials, components, parts, and sub-assemblies needed to create a product. Essentially, you can think of a bill of materials as an ingredient list or recipe for manufacturing an end product. A bill of materials is most commonly used in manufacturing or engineering projects to create physical products, and is less common in software development or intangible creative products like graphic design or written work. A bill of materials can cover several stages of a product, from the design to the order to the build to the maintenance.

Several parties often interact with or depend on a bill of materials, including internal departments, industry experts, project or product stakeholders, and external vendors or suppliers. Therefore, it is essential to have an accurate, comprehensive, and up-to-date list of all the raw materials you will need to successfully complete your product.

“A bill of materials can come in many different flavors,” says Pritchard. “Its intricacy and importance can vary depending on the size of the business, complexity of the product, and risk to the end customer (e.g., medical device vs. general consumer electronics product).” Below is a list of the most common types of BOMs:

- Modular BOM: In a modular BOM, you list components hierarchically to describe all sub-assemblies within the completed product. A single-level BOM has only one level of sub-assemblies, while multi-level or indented BOMs have multiple levels. The components are organized in parent-child relationships from left to right and appear “indented” or on multiple levels.

- Engineering BOM (EBOM): An EBOM is a bill of materials that depicts the product components as designed by the engineers. This differs from a modular BOM in that it reflects the engineering needs, rather than simply listing required materials.

- Manufacturing BOM (MBOM): An MBOM lists all the physical parts needed to successfully manufacture a product. It is different from an EBOM in that it does not focus on the engineering design, but rather on the tangible parts and how they relate to each other.

- Configurable BOM (CBOM): A configurable BOM relies on a modular BOM structure, but is used for products that offer many different options or arrangements. Because users will need to reorganize part combinations for each variation, most organizations use “configurator” software for CBOMs, although you can also manage them manually.

- Equipment BOM: This is another BOM variation that uses the modular structure. As opposed to a traditional BOM, an equipment BOM lists all the tools and equipment needed to make a product, rather than the underlying materials.

What You Should Include in a Bill of Materials

While your BOM will vary based on the specific industry or product, it will usually cover the same basic information about each part or component needed to create the product. For some companies or projects, a simplified version may be appropriate (often called a pseudo-BOM), but to be safe, you’ll want to account for all of the following:

- Product Name: Name of the final product

- Part Name: Name of the part or component

- Part Number: Assigned number for each part or component, making it easy to locate

- Description: Short description of the part or component function so that the reader understands the need

- Quantity: List of unit quantities needed for each part (You will likely have to look at historical data to accurately calculate this number - to learn more about inventory planning, read “Inventory Management 101: From Simple Inventory to Cloud-Based Management.”)

- Unit of Measure: Appropriate metric for each part (for example, yards, cubic centimeters, or gallons)

- Supplier/Vendor: Supplier names and contact information, if you will procure parts from an external vendor (rather than making it in-house)

- Unit Cost: Cost per unit of each part or component - including the unit cost - to scale your production should another order be necessary

- Total Cost: Total cost of each component - calculated by multiplying the quantity by the unit cost

The following items are also often helpful to include, but are not necessary in basic BOMs:

- BOM Level: For hierarchical (modular) BOMs, note at what level this part (or the assembly of this part) occurs.

- Picture: You can include a visual of the part for reference.

- Validation: If necessary, include a space for staff or supplier approval, along with the dates of approval.

- Material Ratio: If you plan to build a product again, you might include the ratios of each part, so you can scale the operation for the next run.

- Waste Percentile: If you need to report wasted material, you can include the percentage of each part that will be used and go to waste. This projection can also help with inventory planning for the the next product order.

- Contact Information: This can be contact information for the relevant internal parties, including team members, management, stakeholders, or any external vendors or suppliers.

- Making vs. Buying: You can also include a space to designate whether you are making or buying each part or component.

Bill of Material Best Practices

While creating a bill of materials is relatively straightforward, there are some best practices that will keep your records clean and organized so that you can maximize production efficiency and drive successful, repeatable results. According to Pritchard, these are the three key traits that are important to any BOM:

- Accuracy: “The accuracy of the BOM can greatly impact the performance of the product in the field. This seems obvious at first, but subtle decisions can have unexpected consequences. For example, in the electronics industry, a typical BOM includes line items (rows of unique items) of all the electrical components and their quantities. Some of these (usually resistors and capacitors) can be swapped with alternative manufacturers on the fly if others are more readily available. If the BOM doesn’t specify the necessary tolerances of the components, there can be dire consequences. It is important to supply as much accurate information in the BOM as possible for a product that has been designed for manufacture (DFM) so that when you need to consider alternatives or make unexpected changes, there are no hiccups during production. Further, quality control practices (which can be automated in the system used to store the BOM) can help ensure information critical to the performance of the product is included,” says Pritchard.

- Scalability: “One option [in order to successfully scale] is to have a simple spreadsheet with a record of each line item’s pricing scheme. As the BOM is scaled, each line item can refer to the correct price. It is not uncommon for CAD systems to refer directly to online databases provided by the manufacturer to obtain pricing information to ensure that their BOM and budget are accurate,” he notes.

- Traceability: “Whether you are developing a simple product in the consumer space or a heavily regulated medical technology, the ability to trace what components and materials were used from where is important to succeed in the long run. Providing sufficient information in the BOM can help in identifying issues in the field, which can be life threatening in certain situations,” Pritchard concludes.

To ensure that your BOM is accurate, scalable, and traceable, adhere to the following four best practices:

Document each and every component. Failure to do so can lead to extra costs or delays.

Keep records of support documentation. To ensure that everyone has access to background information, contracts, and any other relevant material, maintain records of all support documentation.

Control for revisions. Every product launch is subject to changes, and often many parties are involved. To keep everyone up to date and to avoid confusion, label updated copies clearly. You can also use software that updates in real time to manage version control issues.

Complete inventory checks prior to creating a BOM. Because a BOM can serve as a “spare parts” lists, you should build it off existing inventory. Otherwise, you might order duplicate parts and end up wasting material, time, and money.

Benefits and Challenges of Using a Bill of Materials Template

To simplify your process and ensure you include all the necessary information, you can use a bill of materials template. The main benefits of using a template include the following:

- Quality: You’ll create a consistent ordering processes, thus ensuring that you have all the information you need to create a successful, up-to-standard product.

- Flexibility: While templates provide a guide to what you should include in your bill of materials, you can always customize the template to fit your needs.

- Standardized Communication: Using a template encourages you to follow the same communication procedures for ordering materials for every production cycle. This way, all stakeholders — team members, suppliers, vendors, management — can adhere to the process to accurately list all your part needs and support information.

- Controlled Inventory Levels: If you use templates accurately and repeatedly, they can help you project inventory needs, so you can plan ahead and lower your waste.

- Successful Product Realization: Ultimately, using a bill of materials template will best set you up for a successful production cycle.

However, there are some downsides to using a BOM template:

- Version Control: As mentioned earlier, having several versions (created from the same template) can get confusing, especially when multiple parties are involved. Ensure you have a way to keep all the versions organized.

- Security and Access Control: Be mindful of how you distribute static documents, which don’t typically need login credentials to view them. Set standards with your team to ensure that information stays within the organization or among approved external stakeholders and vendors.

- Change Management: It can be difficult to introduce changes — both with products and processes — when you have a precedent of using a specific template. You can learn more about how you can engender change and gain buy-in by reading “8 Steps for an Effective Change Management Process.”

To combat some of these challenges, you can use an online management system to keep track of all documentation. Many organizations opt for cloud-based software, which lets them more easily track changes, share with multiple parties, control permission levels, and iterate over time. While a variety of general online platforms are suitable for managing BOMs, you can also opt for a more specialized program such as inventory control software or materials requirements planning (MRP) software, depending on your needs.

In the following sections, you’ll find several free, downloadable templates for Word and Excel that you can use for specific material tracking situations.

Beyond BOM Templates: Improve Production Planning with Smartsheet for Project Management

From simple task management and project planning to complex resource and portfolio management, Smartsheet helps you improve collaboration and increase work velocity -- empowering you to get more done.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.